Eccentric Plug Valve: A High-Performance Fluid Solution

In the field of industrial fluid control, valves, as key equipment components, have performance and reliability that directly affect the stable operation of the entire system. As a new type of valve design, the eccentric plug valve, with its unique structure and excellent performance, is gradually becoming the preferred choice in numerous industrial applications. This article will provide an in-depth exploration of the characteristics, advantages, application scenarios, as well as installation and maintenance considerations of the eccentric plug valve, helping you fully understand this efficient and reliable industrial valve.

Core Advantages of the Eccentric Plug Valve

The eccentric plug valve stands out among many valve types, primarily due to a series of unique core advantages. These advantages not only allow it to outperform traditional plug valves in terms of performance but also demonstrate higher reliability and cost-effectiveness in practical applications.

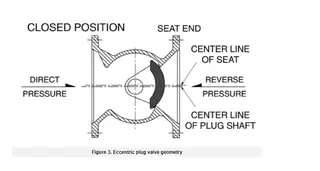

1. Innovative Eccentric Sealing Design

The most notable feature of the eccentric plug valve is its eccentric sealing design. Compared with traditional plug valves, this unique structure significantly reduces operating torque. When the valve is closed, the plug and the valve seat, through the principle of eccentric motion, tighten as they rotate, ensuring the valve's seal. When opening, the plug quickly disengages from the seat, avoiding contact wear, thereby extending the valve's service life. This design not only improves operational convenience but also reduces maintenance costs.

2. Exceptional Wear and Corrosion Resistance

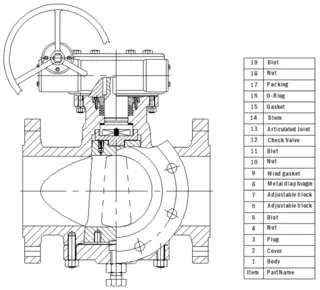

The valve seat of the eccentric plug valve uses a nickel content of 90% with a 3mm thick weld overlay seat or a high-performance resin seat, capable of meeting various corrosion resistance requirements. Its V-shaped composite sealing ring can be replaced without removing the actuator, greatly enhancing maintenance convenience. Additionally, the valve's grease injection port design can further extend its service life. The valve stem bearing uses self-lubricating material, requiring no additional grease, minimizing wear on the valve stem, and further improving durability.

3. Efficient Fluid Control Performance

The valve body adopts a molded heat-bonded rubber process, eliminating concerns about rubber shedding or intermediate layer corrosion. The bonnet and valve body are sealed with O-rings, with fewer bolts, facilitating maintenance. The valve provides inlet and outlet pressure gauge ports, convenient for users to monitor and measure flow. Its straight-through flow path and cylindrical body design prevent sediment accumulation, ensuring smooth fluid flow. The valve's opening indication and memory functions provide great convenience for user operation.

Eccentric Plug Valve Outstanding Performance

The eccentric plug valve exhibits excellent performance, mainly in the following aspects.

1. Low Friction and Zero Leakage

The double-eccentric design of the eccentric plug valve ensures low-friction operation during opening and closing, achieving zero leakage. This design not only improves the valve's sealing performance but also reduces wear caused by friction, extending the valve's service life. In practical applications, whether dealing with clean liquids or media containing solid impurities, the eccentric plug valve maintains excellent sealing performance.

2. Corrosion Resistance and High Strength

The valve seat can be made of pure nickel, stainless steel, or other special materials according to different working media and is compounded with the valve body using new surface treatment technology. This design enables the valve to resist erosion from various media and to operate in harsh working environments. At the same time, the valve body is made of high-strength ductile iron, reducing weight by more than 20% compared with traditional plug valves, not only enhancing valve strength but also lowering installation and maintenance costs.

3. Flow Regulation and Linear Control

The straight-through flow path design and rectangular valve seat cross-section of the eccentric plug valve result in minimal head loss and excellent linear flow control. This design not only improves flow control accuracy but also allows adaptation to various flow regulation requirements. Additionally, the valve provides inlet and outlet pressure gauge ports, facilitating user monitoring and flow measurement, further enhancing operational convenience.

4. Easy Maintenance

The top-entry design of the eccentric plug valve makes maintenance very convenient. Normal maintenance operations can be carried out without removing the entire valve from the pipeline. This design significantly reduces maintenance time and costs, improving equipment operation efficiency. Meanwhile, the valve's opening indication and memory functions provide great convenience for user operation.

Eccentric Plug Valve Wide Applications

The eccentric plug valve is suitable for a variety of industrial applications, including municipal sewage, industrial wastewater, slurry, and clean water environments. Its excellent sealing and corrosion resistance allow it to adapt to harsh working conditions, serving as a shut-off or regulating device.

1. Municipal Sewage and Industrial Wastewater

In municipal and industrial wastewater treatment, the eccentric plug valve effectively prevents leakage, reducing environmental pollution. Its rectangular straight-through flow path and self-flushing design allow the valve to prevent sediment accumulation when handling wastewater containing solid impurities, maintaining smooth flow and sealing performance.

2. Slurry Handling

Slurry, as a highly viscous medium containing numerous solid particles, imposes high demands on valve sealing and wear resistance. The eccentric sealing design and high-strength materials of the eccentric plug valve enable it to effectively withstand slurry erosion and wear, maintaining stable sealing performance and ensuring normal operation of the slurry handling system.

3. Clean Water Transmission

In clean water systems, the low head loss and linear flow control of the eccentric plug valve allow efficient flow management. Its high-strength ductile iron body and non-toxic epoxy resin electrostatic spray surface not only ensure valve strength and corrosion resistance but also make it suitable for harsh environments, including outdoor and underground installations.

Eccentric Plug Valve Installation & Maintenance

Correct installation and maintenance are crucial for ensuring the long-term stable operation of eccentric plug valves.

1. Eccentric Plug Valve Installation Considerations

Installation Orientation: The orientation of the valve during installation is critical for operational efficiency and service life. For clean liquids or gases, whether installed vertically or horizontally, the valve should be oriented so that fluid flows toward the back of the plug. This orientation facilitates optimal sealing and flow control. When handling media with suspended solids or dirty gases, valve orientation is crucial to prevent particle accumulation inside the valve. In vertical installations, the valve seat should face upwards to prevent solids from settling into the valve body when closed. In horizontal installations, the valve should be oriented so that fluid flows across the plug surface, ensuring solids are flushed away during closure rather than remaining inside the valve.

Seal Inspection: During installation, carefully check the valve's sealing performance, ensuring all seals are correctly installed and undamaged. Pay particular attention to the O-ring seals between the bonnet and body, ensuring proper placement without twisting or damage.

Pipeline Connection: The connection between the valve and pipeline should be firm and leak-free. Avoid excessive stress on the valve during connection to prevent compromising sealing performance and service life.

2. Eccentric Plug Valve Maintenance Considerations

Regular Inspection: Periodically inspect the valve's sealing performance and operational flexibility to identify and address potential issues promptly. Inspections should include checking seal wear, seat integrity, and stem lubrication.

Seal Replacement: Replace worn or damaged seals promptly. The V-shaped composite sealing ring design of the eccentric plug valve allows seal replacement without removing the actuator.

Lubrication Maintenance: Although the valve stem bearings use self-lubricating materials, periodic checks of stem lubrication are recommended to ensure normal operation over extended use.

Cleaning and Anti-Corrosion: Regularly clean valve surfaces to prevent debris accumulation and corrosion. For valves installed in harsh outdoor or underground environments, periodically check the integrity of anti-corrosion coatings and reapply if necessary.

Conclusion

With its unique eccentric sealing design, excellent performance, and broad industrial applications, the eccentric plug valve is gradually becoming the ideal choice in industrial fluid control. Its features of low friction, zero leakage, corrosion resistance, high strength, and excellent linear flow control allow it to adapt to harsh working environments as a shut-off or regulating device. Proper installation and maintenance are key to ensuring long-term stable operation. By selecting the correct installation orientation, regularly inspecting sealing performance, replacing seals promptly, and maintaining lubrication and cleanliness, the service life of the valve can be effectively extended, improving overall equipment efficiency.

Send your message to this supplier

Related Articles from the Supplier

What are Eccentric Segmented Ball Valves?

- Aug 27, 2025

The Development of Triple-Eccentric Butterfly Valves

- Jan 18, 2025

What is Double Eccentric Segmented Ball Valve

- Jan 13, 2026

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/eccentric-plug-valve-a-high-performance-fluid-solution.html