Industry Definition & Scope

The farm machinery and equipment industry encompasses the design, manufacturing, distribution, and maintenance of powered devices and implements used in agricultural production. This critical sector provides the mechanical infrastructure for modern farming, enabling the cultivation, planting, tending, harvesting, and primary processing of crops and livestock. The industry serves a global market ranging from small-scale family farms to large-scale commercial agricultural operations.

Key Product Categories

By Primary Function:

-

Tillage & Soil Preparation Equipment: Tractors, plows, harrows, cultivators, and seedbed preparation machinery.

-

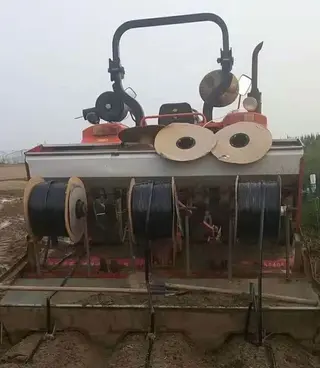

Planting & Seeding Equipment: Seed drills, planters, transplanters, and fertilizer applicators.

-

Crop Care & Protection Equipment: Sprayers (for pesticides, herbicides, fertilizers), irrigation systems, and crop dusters.

-

Harvesting Equipment: Combine harvesters (for grains), forage harvesters, cotton pickers, sugarcane harvesters, potato harvesters, and specialized fruit/vegetable harvesters.

-

Hay & Forage Equipment: Mowers, conditioners, rakes, balers (round, square), and wrappers.

-

Material Handling & Transportation: Farm wagons, trailers, conveyor belts, grain augers, and loaders.

-

Precision Agriculture Technology: GPS guidance systems, yield monitors, variable rate technology (VRT) components, drones, and soil sensors.

-

Livestock Equipment: Milking machines, feeders, waterers, ventilation systems, manure spreaders, and veterinary handling equipment.

-

Farmstead Equipment: Grain dryers, silos, storage bins, and basic processing equipment.

By Power Source & Scale:

-

Two-Wheel Tractors & Walk-Behind Equipment: For small farms, specialty crops, and developing regions.

-

Utility & Row-Crop Tractors: The core power units of modern farms, available in various horsepower ranges.

-

Self-Propelled Implements: Large, dedicated machines like combines and forage harvesters with their own engine and cab.

-

Drawn & Mounted Implements: Equipment pulled or mounted behind a tractor (e.g., plows, planters, balers).

-

Electric & Alternative-Power Equipment: Emerging segment including electric tractors and implements powered by batteries, hydrogen, or biofuels.

Technology & Innovation Trends

-

Precision Agriculture & Digital Farming: Integration of GPS, IoT sensors, AI, and data analytics to optimize field inputs, monitor crop health, and enable site-specific management.

-

Automation & Robotics: Development of autonomous tractors, robotic weeders, harvesting robots, and drones for scouting and spraying.

-

Data Integration & Farm Management Software: Platforms that collect and analyze data from multiple sources (machinery, weather, soil) to support decision-making (Farm Management Information Systems - FMIS).

-

Advanced Telematics & Remote Monitoring: Machine connectivity for tracking location, performance, fuel consumption, and scheduling predictive maintenance.

-

High-Efficiency & Conservation-Focused Design: Equipment that supports minimum tillage, cover cropping, and other regenerative agriculture practices to improve soil health and reduce environmental impact.

-

Alternative Power Trains: Increased R&D into electric, hybrid, and hydrogen fuel cell systems to reduce carbon emissions and dependence on fossil fuels.

-

Modular & Multi-Functional Equipment: Versatile platforms that can perform multiple tasks with quick-change attachments to improve utilization and reduce capital investment.

Global Market Drivers

-

Global Food Security & Population Growth: Need to increase agricultural productivity to feed a growing global population.

-

Labor Shortages & Rising Labor Costs: Driving mechanization and automation adoption to reduce dependency on manual labor.

-

Farm Consolidation & Increasing Farm Size: Larger-scale operations require more powerful, efficient, and technologically advanced equipment.

-

Government Subsidies & Support Programs: Financial incentives in many regions for farmers to purchase modern equipment or adopt precision agriculture technologies.

-

Climate Change & Sustainability Pressures: Need for equipment that enables resource-efficient farming, reduces greenhouse gas emissions, and adapts to changing weather patterns.

-

Commodity Price Volatility: Influences farmers' purchasing power and investment decisions in machinery.

-

Growth in High-Value Specialty Crops: Drives demand for specialized harvesting and handling equipment for fruits, vegetables, and nuts.

Industry Value Chain

-

Raw Material & Component Suppliers: Steel, rubber, electronics, hydraulic components, and engine manufacturers.

-

Original Equipment Manufacturers: Companies that design and assemble complete machines (e.g., John Deere, CNH Industrial, AGCO, Kubota).

-

Implement & Attachment Manufacturers: Specialized companies producing tillage, planting, or harvesting implements.

-

Technology & Software Providers: Companies developing precision ag hardware, software, and data platforms.

-

Dealer & Distribution Networks: Local and regional dealerships providing sales, parts, and service.

-

Financing & Insurance Providers: Crucial for enabling large capital purchases through loans, leases, and insurance products.

-

End Users (Farmers & Agricultural Enterprises): Ranging from smallholders to large corporate farms.

Key Industry Challenges

-

High Capital Intensity & Cyclical Demand: Equipment represents a major investment, and purchases are often deferred during periods of low farm income.

-

Geopolitical & Trade Tensions: Tariffs and trade disputes can disrupt supply chains and affect market access.

-

Rapid Technological Change & Integration Complexity: Keeping pace with innovation and ensuring different technologies (from various vendors) work together seamlessly.

-

Data Ownership, Privacy, & Interoperability Issues: Concerns about who owns and can use farm data generated by smart equipment, and lack of common data standards.

-

Skilled Technician Shortage: Difficulty in training and retaining service technicians capable of repairing increasingly complex, software-driven machinery.

-

Pressure to Reduce Environmental Footprint: Regulatory and societal expectations to develop cleaner, more sustainable equipment.

-

Varied Global Farming Conditions: Need to design equipment adaptable to diverse crops, terrains, scales, and farming practices worldwide.

Future Outlook

The industry is undergoing a fundamental shift from manufacturing mechanical hardware to providing integrated, data-driven agricultural solutions.

-

Rise of the "Smart Farm": Ubiquitous connectivity and data exchange between machines, fields, and farm management systems.

-

Equipment-as-a-Service Models: Growth of subscription-based access to equipment, technology, and data analytics rather than outright ownership.

-

Increased Autonomy: Gradual adoption of fully autonomous machinery for specific, repetitive tasks (e.g., tillage, mowing, spraying).

-

Circular Economy & Lifecycle Management: Greater focus on remanufacturing, rebuilding, and recycling equipment to extend lifecycles and reduce waste.

-

Collaborative Robotics: Small, collaborative robots working alongside traditional machinery or performing delicate tasks in high-value crops.

-

Hyper-Precision & Micro-Management: Ability to manage plant-by-plant or animal-by-animal based on real-time data from sensors and imaging systems.

-

Regional Product Adaptation: More tailored equipment solutions for specific regional crops, climates, and farming systems in growth markets.