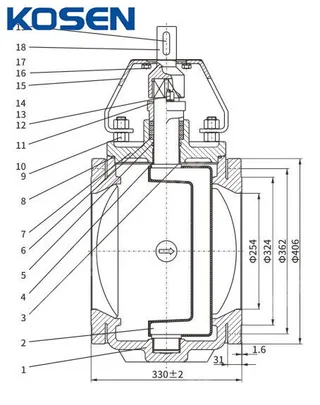

Elastic Seat Eccentric Plug Valve, API 6D, GGG40, DN800, PN10

Key Specifications / Features

Detail Information

Product Name: Elastic Seat Eccentric Plug Valve

Design Standard: API 6D, API 599

Body Material: Ductile Iron GGG40

Size: DN800, 32 Inch

Pressure: PN10, Class 150 LB

End Connection: RF Flanged

Operation: Wormgear

The elastic seat ring-sealed eccentric plug valve is a new design that fills the gap left by traditional plunger and ball valves in large-diameter pipelines (above DN200) and applications involving muddy water and sludge. With excellent sealing performance, corrosion resistance, low opening/closing torque, minimal water flow loss, and a long service life, this valve is ideal for regulating or closing flow in applications such as urban sewage, industrial wastewater, sludge, and clear water systems.

Technical Specifications

» Structure: Elastic Seat Eccentric Plug Valve

» Nominal Diameter: NPS 2-36 Inch (DN50-DN900)

» Design Pressure: Class 150-900 LB (PN20-PN150)

» Materials: Ductile Iron, Carbon Steel, Stainless Steel, Aluminum Bronze, Duplex Steel, etc.

» Design Standards: API 6D, API 599

» Face-to-Face: ASME B16.10

» Connection Ends: RF, RTJ

» Test Standards: API 598, ISO 5208

» Design Temperature: -29°C to +180°C

» Applicable Mediums: Water, steam, oil, gas, etc.

» Operation: Lever, Gearbox, Electric, Pneumatic, Hydraulic

Working Principle

The elastic seat-sealed eccentric structure, combined with the crank cock, provides sufficient strength to withstand high pressure and transmit torque. It also creates a large flow area by effectively avoiding obstruction in the fully open valve passageway. The rubber coating, applied through a heat vulcanization molding process, ensures a firm bond between the rubber and the internal iron core, a smooth exterior surface, precise sealing face dimensions, and improved corrosion resistance, thus extending the valve's service life and enhancing sealing reliability and interchangeability. The corrosion-resistant alloy-surfaced valve seat features a small sealing contact area and introduces eccentricity in the center of the cock sealing face, ensuring zero leakage, reducing the valve's opening/closing torque, and prolonging its lifespan. The rectangular flow section provides a suitable linear regulation characteristic when used as a regulator.

The valve's opening and closing are achieved through the eccentric motion of the cock and valve body. There is eccentricity between the cock and valve body, as well as between the valve seat and the center of the cock's gyration. When the cock body rotates 90 degrees from the fully open to the fully closed position, the sealing face of the cock body aligns with the valve seat, ensuring a reliable seal for closure.