What is Double Eccentric Segmented Ball Valve

The Double Eccentric Segmented Ball Valve is a high-performance industrial valve specifically designed for complex and severe operating conditions. Structurally, it integrates the advantages of conventional ball valves, V-port valves, and orbit ball valves. By means of a unique double-eccentric sealing principle, it achieves a combination of low wear, low operating torque, and highly reliable sealing during opening and closing. Compared with traditional ball valves, the double eccentric segmented ball valve exhibits superior stability under high-temperature, high-pressure, severe abrasion, and particulate-laden media conditions. It ensures long-term zero-leakage operation while remaining easy to adjust and maintain. As a result, it has been increasingly and widely applied in pipeline control systems in industries such as metallurgy, power generation, chemical processing, and mining.

Structural Characteristics of Double Eccentric Segmented Ball Valve

The Double Eccentric Segmented Ball Valve is a newly developed product created by incorporating the advantages of various valve designs, including ball valves, V-type valves, and orbit ball valves. Its core feature is the double-eccentric sealing structure, which significantly reduces wear and operating torque during service while providing excellent sealing performance and a long service life. The valve seat and the segmented (hemispherical) ball are subjected to special hardening treatments, enabling them to meet demanding requirements such as wear resistance, erosion resistance, corrosion resistance, and high-temperature resistance under harsh operating conditions.

Structurally, the Double Eccentric Segmented Ball Valve is similar to a triple-offset metal-seated butterfly valve. It is easy to operate, features friction-free opening, and achieves zero leakage. The sealing pair (valve core and valve seat) adopts a bi-metallic construction, forming a metal-to-metal spherical band seal with fire-safe and explosion-proof characteristics. Sealing between the valve core and the valve seat is achieved through spherical line contact, and zero leakage is realized by means of three-dimensional eccentricity. A compensation allowance is reserved on the valve core of the sealing pair. After long-term operation, if wear of the sealing surfaces is detected, reliable sealing can still be achieved simply by loosening the stop bolt on the handwheel side and slightly increasing the closing rotation, thereby extending the service life of the valve.

In addition, the compression sleeve of the Double Eccentric Segmented Ball Valve can be removed, allowing convenient adjustment or replacement of the valve seat. This enables continued use of the valve even after sealing performance has degraded, avoiding the disadvantage of traditional valves that must be completely scrapped once the seal fails. By hardfacing different alloys (or using composite balls), the bi-metal sealing pair can be optimally selected to suit applications requiring wear resistance, corrosion resistance, high-temperature resistance, and strict sealing performance.

Working Principle of Double Eccentric Segmented Ball Valve

The Double Eccentric Segmented Ball Valve utilizes an eccentric valve body, an eccentric segmented ball, and a valve seat. As the valve stem rotates, the components automatically self-center along a common trajectory. During the closing process, the valve becomes progressively tighter, ultimately achieving an excellent sealing effect. When the valve is fully open, the segmented ball completely disengages from the valve seat, leaving a certain clearance.

The rotational radius consists of a long radius and a short radius. The tangent of the long-radius rotational path forms an angle θ with the sealing surface of the valve seat. During opening and closing, the segmented ball gradually disengages from and then gradually compresses against the valve seat surface. This action significantly reduces mechanical wear and scuffing between the valve seat and the segmented ball during operation, thereby extending the service life of the valve.

The valve seat adopts a floating design, which reduces machining difficulty and ensures that the centerline of the valve seat coincides with the center of the spherical surface of the segmented ball, thus improving sealing performance. A clearance exists between the valve seat and the valve body. During assembly, the segmented ball is used for positioning, allowing automatic alignment of the centerline and ensuring full contact between the sealing surface of the valve seat and the spherical surface of the segmented ball. This design effectively eliminates leakage caused by machining tolerance errors and enhances overall valve performance and longevity. The seal between the valve seat and the valve body is a metal-to-metal hard seal, making it suitable for high-temperature and high-pressure applications.

Performance Advantages of Double Eccentric Segmented Ball Valve

Before exploring the wide range of applications of the Double Eccentric Segmented Ball Valve, it is essential to first examine the performance advantages that make it so highly regarded. These advantages not only allow it to stand out among various valve products, but also constitute the key factors that enable it to adapt to a wide variety of complex operating conditions. In the following section, the performance advantages of the Double Eccentric Segmented Ball Valve will be discussed in detail.

1. Excellent Sealing Performance

The sealing pair of the Double Eccentric Segmented Ball Valve consists of the valve core and valve seat made of bi-metallic materials, forming a metal-to-metal spherical band seal. This sealing method is not only fire-safe and explosion-proof but also extremely reliable. Sealing between the valve core and the valve seat is achieved through spherical line contact, and zero leakage is realized through three-dimensional eccentric design. Even after extended service, if wear occurs on the sealing surfaces, reliable sealing can still be achieved by slightly adjusting the closing position, thereby prolonging valve service life. Furthermore, the hard-seal structure between the valve seat and valve body, together with the dual hard-seal design between the valve seat and valve body and between the valve seat and segmented ball, further ensures sealing integrity under high-temperature and high-pressure conditions.

2. Low Wear and Long Service Life

Thanks to its double-eccentric design, the segmented ball and valve seat of the Double Eccentric Segmented Ball Valve remain almost entirely in a free-running, non-contact state during opening and closing. External force is applied only at the instant of disengagement or compression. This structure greatly reduces mechanical wear between the segmented ball and the valve seat, effectively extending the service life of the valve. Compared with conventional ball valves, wear during operation is minimal, operating torque is low, and handling is light and smooth. The floating valve seat further reduces machining difficulty and wear risk. Even under high-temperature and high-pressure conditions, the valve maintains excellent sealing performance and long service life.

3. Capability to Withstand Harsh Operating Conditions

The valve seat and segmented ball of the Double Eccentric Segmented Ball Valve undergo special hardening treatments, making them particularly suitable for harsh conditions requiring wear resistance, erosion resistance, corrosion resistance, and high-temperature resistance. The sealing pair can be hardfaced with different alloys according to specific service requirements, enabling it to handle media with severe abrasion, rapid erosion, or strong corrosion. For example, when the sealing surfaces are hardfaced with Cr-Mn-Si hard alloy and provided with fire-safe, explosion-proof, and anti-static features, the valve is suitable for medium-to-high-temperature services such as coal gas, coke oven gas, water gas, and natural gas.

Moreover, the instant disengagement and instant compression characteristics between the segmented ball and the valve seat allow the valve to operate reliably in particulate-laden media. It is widely used in metallurgical, mineral processing, and power generation processes, such as pulverized coal injection systems, milling systems, and dust collection pipelines. During instant disengagement and compression, a squeezing and shearing action occurs between the segmented ball and the valve seat, removing scale and adhesion from the sealing surfaces and ensuring tight and reliable sealing.

4. Easy Operation and Convenient Maintenance

Operation of the Double Eccentric Segmented Ball Valve is extremely simple. A 90-degree rotation of the valve stem completes opening or closing, providing fast and effortless operation. Similar to a triple-offset metal-seated butterfly valve, it features friction-free opening, zero leakage, and long service life. Maintenance is also highly convenient. For example, the compression sleeve can be removed to adjust or replace the valve seat, allowing the valve to remain in service and avoiding the need to scrap the entire valve after seal failure. The valve adopts a modular design with a simple structure, high reliability, and good interchangeability, which further reduces maintenance cost and downtime.

Application of Double Eccentric Segmented Ball Valve

- Steel Industry: In steel production, the Double Eccentric Segmented Ball Valve is used in pulverized coal injection systems, milling systems, and dust collection pipelines. Its instant disengagement and compression characteristics make it suitable for severe particulate-laden conditions, effectively reducing wear caused by coal powder and ensuring tight and reliable sealing.

- Aluminum Industry: In aluminum production, the valve is applied in pipeline systems conveying aluminum powder, alumina, and other particulate media. Its excellent wear resistance, erosion resistance, corrosion resistance, and high-temperature resistance meet the stringent requirements of aluminum processing and ensure stable operation.

- Pulp and Paper Industry: During papermaking, the conveyance of pulp and similar media requires high sealing performance and wear resistance. The sealing pair of the Double Eccentric Segmented Ball Valve can be hardfaced with different alloys to meet various operating conditions, effectively preventing corrosion and wear caused by pulp media and ensuring reliable pipeline operation.

- Petrochemical Industry: In the petrochemical sector, the valve is used for conveying petroleum gas, natural gas, and similar media. Its fire-safe, explosion-proof, high-temperature-resistant, and corrosion-resistant characteristics ensure safe operation in hazardous environments and help prevent leakage-related accidents.

- Power Industry: In power generation, slag handling systems and coal-handling and milling systems place extremely high demands on valve wear resistance and reliability. The instant disengagement and compression characteristics of the Double Eccentric Segmented Ball Valve effectively remove scale and adhesion from sealing surfaces, ensuring tight sealing. It is an ideal choice for handling two-phase mixed-flow media such as mineral slurries, pulp, ash, and slag in processes where precipitation, scaling, or crystallization is likely to occur.

Maintenance of Double Eccentric Segmented Ball Valve

To ensure long-term stable operation, regular maintenance and care are essential. The following practices are recommended:

- Regular Inspection: Periodically inspect sealing performance to check for leakage. Examine wear conditions of the valve seat and segmented ball to identify and address potential issues in a timely manner. Also verify that connections between the valve stem, bracket, and actuator are secure to ensure reliable operation.

- Cleaning and Lubrication: Regularly clean both the exterior and interior of the valve to remove dust, debris, and contaminants that could affect performance. Apply lubricant periodically to moving components such as the valve stem to reduce friction and extend service life.

- Adjustment and Replacement: If sealing performance declines, promptly adjust the compensation allowance of the sealing pair to restore sealing integrity. When wear of the valve seat or segmented ball becomes severe, replace the affected components in time to prevent production accidents caused by seal failure.

- Professional Maintenance: For complex maintenance tasks, it is recommended to engage qualified technical personnel who can accurately diagnose issues and implement effective repair and maintenance measures.

Conclusion

As a new category of ball valve, the Double Eccentric Segmented Ball Valve is becoming an ideal choice for industrial pipeline control due to its unique structural design, outstanding performance advantages, and wide range of applications. Its friction-free operation, wear-resistant sealing, and low operating torque not only improve production efficiency but also significantly reduce maintenance costs. Across industries such as steel, aluminum, pulp and paper, petrochemical processing, and power generation, the Double Eccentric Segmented Ball Valve has demonstrated exceptional adaptability and reliability. With continued industrial development and increasing performance demands on valves, this valve type will play an increasingly important role in future industrial pipeline control systems.

Send your message to this supplier

Related Articles from the Supplier

What is Double Eccentric Segmented Ball Valve

- Jan 13, 2026

What is a Duplex Spring Safety Valve?

- Sep 17, 2025

What is Explosion-Proof Electric Ball Valve

- Dec 22, 2025

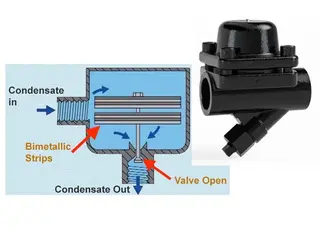

What is Bimetallic Steam Trap?

- Dec 26, 2025

What is Dual Plate Wafer Check Valve

- Jan 05, 2026

What Is a Thermodynamic Steam Trap

- Jan 22, 2026

Related Articles from China Manufacturers

What is Double Eccentric Butterfly Control Valve?

- Jul 18, 2024

What is a Double Eccentric Butterfly Valve?

- Dec 09, 2024

What is a Double Eccentric Butterfly Valve?

- Jul 11, 2025

What is Double Block and Bleed Valves ?

- May 08, 2019

What is Handle Butterfly Valve

- Sep 08, 2015

What is Butterfly Check Valve?

- May 07, 2020

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/what-is-double-eccentric-segmented-ball-valve.html