Eccentric Plug Valve: Design, Performance and Applications

The eccentric plug valve is a highly efficient fluid control device that shares some design similarities with traditional ball valves but also exhibits significant differences in structure and operational principles. It is widely used in industrial systems that require precise fluid flow control and reliable sealing performance. This article delves into the design principles, performance advantages, and diverse applications of eccentric plug valves across various working conditions.

Design Principles of Eccentric Plug Valves

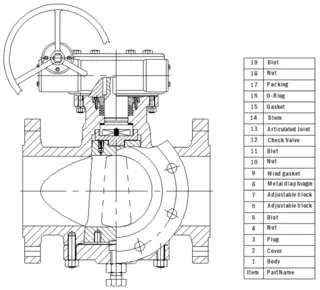

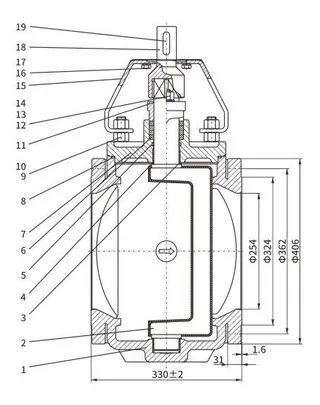

The structure of the eccentric plug valve bears a resemblance to sector-shaped ball valves, particularly in the design of the valve body and stuffing box. However, the most notable distinction lies in the design of the valve core. In a ball valve, the axis of the ball aligns with the valve seat, ensuring constant contact between the ball and the seat. In contrast, the axis of the eccentric plug valve is slightly offset from the valve seat, causing the valve core to remain away from any supporting surface until it is fully closed. This eccentric design, akin to the eccentric cam in high-performance butterfly valves, allows the valve core to achieve superior sealing performance when closed.

Additionally, the valve core of the eccentric plug valve is similar in design to the core of a globe valve and is installed perpendicular to the shaft. The rotating surface of the valve core resembles that of an improved quick-opening valve core, with the added feature of providing a supporting surface for enhanced flow control.

Performance Advantages of Eccentric Plug Valves

Thanks to its unique design, the eccentric plug valve offers exceptional sealing performance and operational characteristics. The flexural deformation of the valve core during closure ensures tight contact with the valve seat, resulting in excellent sealing. Furthermore, the valve's low wear characteristics, dynamic stability, and wide rangeability make it a reliable choice for various fluid control applications.

1. Sealing Performance

The eccentric plug valve excels in sealing performance due to its specialized valve core design. As the valve core approaches closure, the bending arm of the core undergoes flexural deformation, pressing the spherical surface of the core tightly against the valve seat. This ensures outstanding sealing. The valve body and bonnet, manufactured using integral casting, enable stable operation across a wide temperature range (-40°C to 450°C) and pressure range (up to 10 MPa).

2. Reduced Wear and Extended Lifespan

The eccentric plug valve minimizes wear by reducing contact between the plug and the seat ring during opening. This design reduces friction, improving the valve's dynamic characteristics and extending its lifespan. Over time, this design not only lowers maintenance frequency but also enhances system reliability.

3. Rangeability and Flow Control

The eccentric plug valve offers a wide rangeability, making it suitable for precise flow control. Full-cavity valves achieve a rangeability of 100:1, while 60% and 40% reduced-cavity valves offer rangeabilities of 60:1 and 40:1, respectively. The flow capacity of the valve is 1.2 times that of a double-seat valve of the same diameter. Its flow characteristics closely resemble a modified parabolic curve, ensuring consistent flow control accuracy and stability even when fluid direction changes.

4. Dynamic Stability

The eccentric plug valve exhibits excellent dynamic stability. The fluid's torque on the valve core is balanced, resulting in superior dynamic performance compared to piston and butterfly valves. Additionally, the valve core design avoids the undercutting issues common in piston valves, enabling smoother operation.

Design and Application Advantages of Eccentric Plug Valve

The design advantages of eccentric plug valves make them suitable for a wide range of industries. Their eccentric rotating core and unique sealing structure provide excellent sealing performance and efficient flow control. The compact design, ease of operation, and low wear make them ideal for high-temperature, high-pressure, and complex working conditions.

1. Reliable Sealing

Eccentric plug valves ensure low leakage rates, with standard leakage rates below 0.01%. This makes them particularly suitable for applications requiring high sealing performance, especially in fluid flow control. The tight contact between the valve core and seat ensures effective sealing when the valve is closed.

2. Adaptability to Various Conditions

Eccentric plug valves are highly adaptable, excelling in controlling corrosive and particle-laden fluids. The valve body can be lined with materials that offer corrosion and wear resistance, enabling stable operation in harsh conditions.

3. Lightweight and Compact Design

The compact and lightweight design of eccentric plug valves offers flexibility in installation. Whether used as a primary or auxiliary valve, their versatile installation options cater to diverse application needs. Their universal applicability spans industries such as oil and gas, chemical, and power.

4. Easy Maintenance and Replacement

The simple structure of eccentric plug valves facilitates easy disassembly and maintenance. By replacing the valve seat and core components, users can quickly restore the valve to working condition, reducing maintenance costs and improving equipment availability.

Applications of Eccentric Plug Valves

Eccentric plug valves are widely used in several key industries due to their exceptional performance.

Oil and Gas Industry: Eccentric plug valves are extensively used in the transportation and processing of oil and gas, handling high-pressure and high-temperature conditions while providing precise flow control.

Chemical and Pharmaceutical Industry: In these industries, eccentric plug valves are used to control corrosive and particle-laden fluids. Their corrosion and wear resistance make them an ideal choice.

Power Industry: Eccentric plug valves are employed for fluid control and regulation in high-temperature and high-pressure environments, ensuring system stability.

Food and Beverage Industry: These valves are also used in food and beverage processing, meeting strict hygiene and sealing standards.

Conclusion

Eccentric plug valves have gained widespread adoption across various industrial sectors due to their unique design, superior performance, and adaptability. Their excellent sealing performance, low wear, dynamic stability, and ability to handle diverse working conditions make them indispensable for precise flow control and efficient sealing. As technology advances, eccentric plug valves will continue to play a vital role in industrial applications, driving fluid control systems toward greater efficiency, environmental sustainability, and more intelligent.

Send your message to this supplier

Related Articles from the Supplier

What are Eccentric Segmented Ball Valves?

- Aug 27, 2025

The Development of Triple-Eccentric Butterfly Valves

- Jan 18, 2025

What is Double Eccentric Segmented Ball Valve

- Jan 13, 2026

Related Articles from China Manufacturers

Eccentric Plug Valves: Design and Applications

- Aug 29, 2024

What is an Eccentric Plug Valve

- May 20, 2019

How Does an Eccentric Plug Valve Work?

- Oct 26, 2024

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/eccentric-plug-valve-design-performance-and-applications.html