GGG40 Eccentric Plug Valve, API 6D, DN250, PN10, Elastic Seat

Key Specifications / Features

Detail Information

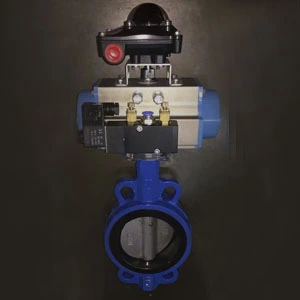

Product Name: Elastic Seat Eccentric Plug Valve

Design Standard: API 6D

Body Material: Ductile Iron GGG40

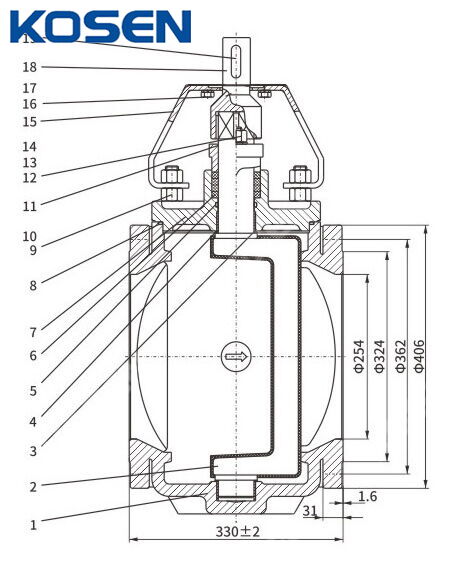

Size: DN250, 10 Inch

Pressure: PN10, Class 150 LB

End Connection: RF Flanged

Operation: Wormgear

The Elastic Seat Ring Sealed Eccentric Plug Valve is a newly designed valve that addresses the limitations of traditional plunger and ball valves, especially in applications involving large-diameter pipelines (above DN200) and environments with muddy water or sludge. With exceptional sealing performance, corrosion resistance, and reduced opening/closing torque, this valve also minimizes water flow loss and boasts a long service life. It is commonly used as a regulator or closure in applications such as urban sewage systems, industrial sewage, sludge management, and clear water systems.

Technical Specifications

» Nominal Diameter: NPS 2-36 Inch (DN50-DN900)

» Design Pressure: Class 150-900 LB (PN20-PN150)

» Materials: Ductile Iron, Carbon Steel, Stainless Steel, Aluminum Bronze, Duplex Steel, etc.

» Design Standards: API 6D, API 599

» Face-to-Face: ASME B16.10

» Connection Ends: RF, RTJ

» Test Standards: API 598, ISO 5208

» Design Temperature: -29°C to +180°C

» Applicable Mediums: Water, steam, oil, gas, etc.

» Operation: Lever, Gearbox, Electric, Pneumatic, Hydraulic

Working Principle

The Elastic Seat Sealed Eccentric Plug Valve operates based on an eccentric structure combined with a crank cock, providing the necessary strength to withstand high pressure and transmit torque. This design also allows for a larger flow area by preventing obstruction in the fully-open valve passage. The rubber coating, applied via heat vulcanization molding, ensures strong adhesion to the internal iron core, smooth surface finish, precise sealing face dimensions, and improved corrosion resistance. This enhances both the durability and the reliability of the valve, as well as the interchangeability of the sealing components.

The corrosion-resistant alloy surfaced valve seat features a small contact area, with an eccentric design on the sealing face to prevent leakage and reduce operating torque. This design significantly prolongs the valve's service life. Additionally, the rectangular flow section helps achieve a linear regulating property when the valve is used for flow control.

The opening and closing of the valve are achieved through the eccentric motion of the cock and valve body. With eccentricity between both the cock and valve body, as well as between the valve seat and the cock’s gyration center, rotation of the cock body by 90 degrees from the fully-open to fully-closed position causes the sealing face to engage with the seat, ensuring a tight seal.