Industry Definition & Scope

The forged steel valves industry involves the design, manufacturing, and distribution of industrial valves produced through forging processes, where steel is shaped under high pressure and temperature to create components with superior mechanical properties. These valves are engineered for demanding applications in high-pressure, high-temperature, and corrosive environments across oil & gas, petrochemical, power generation, and process industries, offering exceptional strength, reliability, and longevity compared to cast alternatives.

Key Product Categories

-

By Valve Type:

-

Forged Steel Gate Valves: For isolation services with minimal pressure drop

-

Forged Steel Globe Valves: For throttling and regulating flow

-

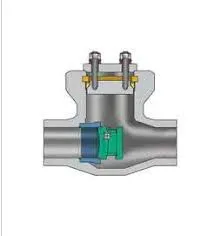

Forged Steel Check Valves: Preventing backflow in piping systems

-

Forged Steel Ball Valves: Quarter-turn valves for shut-off and control

-

Forged Steel Needle Valves: For precise flow control in instrumentation

-

Forged Steel Plug Valves: For on/off and diverting services

-

-

By Material Specifications:

-

Carbon Steel Forged Valves: ASTM A105, A350 LF2 for general service

-

Alloy Steel Forged Valves: ASTM A182 F11, F22, F91 for high-temperature applications

-

Stainless Steel Forged Valves: ASTM A182 F304, F316, F321 for corrosive environments

-

Duplex/Super Duplex: For chloride-rich and offshore applications

-

Special Alloys: Inconel, Monel, Hastelloy for extreme conditions

-

-

By Pressure Class:

-

Standard Classes: ANSI 150, 300, 600, 900, 1500, 2500

-

High-Pressure Specials: API 6A, 10,000 psi and above for wellhead services

-

Nuclear Applications: ASME Section III Class 1, 2, 3

-

-

By End Connection:

-

Socket Weld Ends: For small bore high-pressure piping

-

Threaded Ends: NPT, BSPT for instrument and utility lines

-

Butt Weld Ends: For critical high-integrity systems

-

Flanged Ends: For ease of maintenance and installation

-

Technology & Innovation Trends

-

Advanced Forging Technologies:

-

Closed-die forging for complex geometries and superior grain flow

-

Isothermal forging for precise dimensional control

-

Rotary forging for large diameter valve components

-

Automated forging lines with robotic handling

-

-

Material Science Advancements:

-

Nanostructured steels for enhanced corrosion and erosion resistance

-

High-temperature alloys for ultra-supercritical power plants

-

Cryogenic materials for LNG and industrial gas applications

-

Composite coatings for extended service life

-

-

Digital Manufacturing Integration:

-

Digital twins for forging process optimization

-

AI-based quality prediction and defect detection

-

Blockchain for material traceability and certification

-

IoT-enabled forging presses with real-time monitoring

-

-

Sustainable Forging Practices:

-

Energy-efficient induction heating systems

-

Recycled steel utilization in forging billets

-

Near-net-shape forging reducing material waste

-

Water-based lubricants and eco-friendly quenching media

-

Global Market Drivers

-

Expansion of oil & gas exploration in harsh environments (deepwater, Arctic)

-

Growth in LNG terminals and hydrogen infrastructure development

-

Power plant upgrades and new nuclear plant construction

-

Stringent safety and emission regulations in process industries

-

Replacement of aging valve infrastructure in refineries and chemical plants

-

Increasing demand for high-integrity valves in pharmaceutical and food processing

-

Growth in petrochemical capacity additions in Asia and Middle East

Major Players & Value Chain

-

Global Forging Specialists: Velan, Flowserve, Cameron, KITZ, IMI Critical Engineering

-

Material Experts: Carpenter Technology, Special Metals, VSMPO-AVISMA

-

Regional Leaders: China (Jiangsu Sheye, Dazhong Valve), India (L&T, Audco)

-

Value Chain: Steel mills → billet production → forging → machining → heat treatment → testing → assembly → certification → distribution → end-users

Challenges & Opportunities

-

Challenges:

-

High capital investment in forging equipment and tooling

-

Skilled labor shortage in forging and metallurgical engineering

-

Competition from cast and fabricated valve alternatives

-

Raw material price volatility (alloying elements)

-

Long lead times for custom and specialized valves

-

-

Opportunities:

-

Hydrogen economy valve development and certification

-

Digital valve services including predictive maintenance

-

Additive manufacturing for complex forgings and prototypes

-

Emerging market energy infrastructure projects

-

Service life extension through advanced coatings and refurbishment

-

Integration with smart plant management systems

-