Industry Definition & Scope

The butterfly valves industry involves the design, manufacturing, and application of quarter-turn valves that regulate flow through a disc mounted on a rotating shaft. Characterized by compact design, quick operation, and cost-effectiveness, butterfly valves serve as essential flow control components across water management, HVAC, industrial processing, and energy infrastructure.

Key Product Categories

-

By Design Configuration:

-

Wafer-Type Butterfly Valves: Lightweight design clamped between pipe flanges

-

Lug-Type Butterfly Valves: Threaded inserts for end-of-line or dead-end service

-

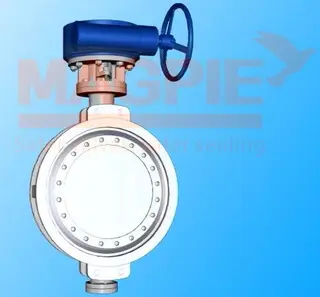

Double Flanged Valves: Integral flanges for high-pressure applications

-

High-Performance Valves: Offset disc design (triple/dual eccentric) for zero leakage

-

Knife-Gate Hybrid Valves: For slurry and viscous media applications

-

-

By Disc & Seat Materials:

-

Disc Materials: Carbon steel (epoxy-coated), stainless steel (316/304), aluminum bronze, nickel-plated, Duplex alloys

-

Seat Materials: EPDM, Nitrile, Viton, PTFE, reinforced PTFE, metal seats (Stellite/Hastelloy)

-

Liner Options: Full rubber lining, PFA lining, ceramic coating for abrasion resistance

-

-

By Application Specifications:

-

Water & Wastewater: Resilient-seated valves (ANSI/AWWA C504 standard)

-

HVAC Systems: Tight-shutoff valves for heating/cooling circuits

-

Chemical Processing: Lined valves for corrosive media (ISO 16136)

-

Marine & Offshore: Certified valves for seawater cooling and ballast systems

-

Food & Pharmaceutical: Sanitary designs with CIP/SIP capability

-

Fire Protection: UL/FM approved valves with fail-safe operation

-

-

By Actuation & Control:

-

Manual Operation: Lever, gear operator, detent mechanism

-

Automated Control: Electric, pneumatic, hydraulic actuators

-

Smart Integration: IoT-enabled with position feedback, torque sensing, predictive diagnostics

-

Modulating Control: Precision control via characterized discs and positioners

-

Technology & Innovation Trends

-

Advanced Sealing Technology:

-

Triple eccentric metal-seated designs for zero-leakage applications

-

Fire-safe certifications to API 607/ISO 10497 standards

-

Cryogenic seat materials for LNG and industrial gases (-196°C)

-

-

Digital Transformation:

-

Wireless valve monitoring via HART/Profibus/Modbus protocols

-

Cloud-based asset management with predictive maintenance algorithms

-

Digital twins for flow characteristic optimization

-

-

Material Science Advancements:

-

Nanocomposite seats extending service life 3-5X

-

Graphene-enhanced coatings for corrosion/erosion resistance

-

Sustainable material development (bio-based elastomers, recycled metals)

-

-

Manufacturing Innovation:

-

Robotic welding for consistent disc-shaft assembly

-

Laser scanning for dimensional accuracy verification

-

Additive manufacturing for customized valve components

-

Global Market Drivers

-

Global water infrastructure investment (desalination plants, smart water networks)

-

Energy transition projects (hydrogen pipelines, carbon capture systems)

-

HVAC market growth driven by green building standards (LEED, BREEAM)

-

Food processing industry automation and hygiene requirements

-

Replacement of aging valves in chemical and power generation facilities

-

Marine industry expansion (cruise ships, LNG carriers, offshore platforms)

Major Players & Value Chain

-

Global Leaders: Emerson, Flowserve, KITZ, Crane, IMI Critical Engineering

-

Water Specialists: DeZURIK, AVK, Hawle, Val-Matic, Bermad

-

Regional Manufacturers: China-centered (Zhejiang, Jiangsu clusters), Indian valve manufacturers

-

Value Chain: Material suppliers → component manufacturing → valve assembly → testing/certification → distributors → system integrators → end-users

Challenges & Opportunities

-

Challenges:

-

Price pressure from standardized product commoditization

-

Material compatibility issues in extreme chemical environments

-

Technical skill gap in proper valve selection and installation

-

Regulatory complexity across different regions and industries

-

-

Opportunities:

-

Smart water network integration for leakage reduction

-

Hydrogen-ready valve development for green energy infrastructure

-

Retrofitting programs for energy efficiency improvement

-

Aftermarket services (diagnostics, repair, digital upgrades)

-

Emerging market growth in Asia-Pacific and Middle East infrastructure

-

Butterfly Valves Product List

Videos of Butterfly Valves

More About Butterfly Valves

What maintenance do butterfly valves typically require?

They are low-maintenance but need periodic checks:

-

Seal/seat: Inspect for wear or compression set.

-

Shaft seals/packing: Check for leaks; adjust or replace as needed.

-

Disc/bearing movement: Ensure smooth operation; lubricate if specified.

-

Actuator linkage: Verify alignment and function.

For metal-seated valves, minimal maintenance is required outside of operational checks.

When should I choose a lug-style over a wafer-style butterfly valve?

Lug-style: Has threaded inserts (lugs); can be bolted to one flange. Use when you need to isolate or remove downstream equipment without disassembling the entire pipeline (common at pump connections or branch lines).