Y Type Tilting Disc Check Valve, A494 CU5MCuC, 10 IN, CL1500

Key Specifications / Features

Detail Information

Product Name: Y Type/Pattern Tilting Disc Check Valve

Design Standard: ASME B16.34

Body Material: ASTM A494 CU5MCuC, Nickel Alloy

Size: 10 Inch, DN250

Pressure: Class 1500 LB, PN250

End Connection: BW End

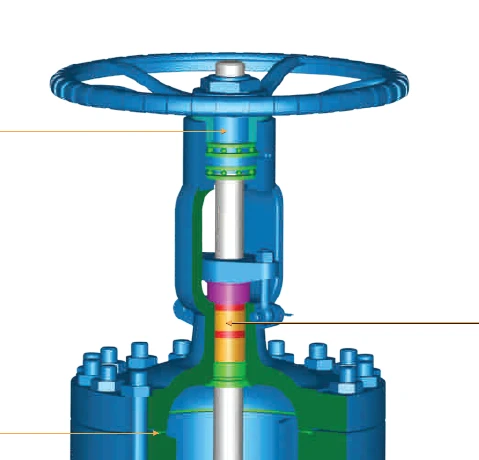

The tilting disc check valve features a pivot point at the center of the disc, designed to address the limitations of conventional swing check valves. Unlike swing check valves, which require higher fluid velocity and cracking pressure to remain open, the tilting disc check valve achieves full and stable opening at lower flow rates. This makes it particularly advantageous in low-pressure conditions, as it minimizes pressure drop compared to swing types. However, at higher flow rates, the tilting disc check valve experiences a slightly higher pressure drop than swing check valves.

Technical Specification

» Nominal Diameter: NPS 2 Inch–24 Inch (DN50–DN600)

» Design Pressure: Class 150–2500 LB (PN10–PN420)

» Temperature Range: -29°C to 595°C

» Material Options:

Carbon Steel: ASTM A216 WCB, WCC

Low Alloy Steel: ASTM A217 WC6, WC9, C5, C12A

Low-Temperature Carbon Steel: ASTM A352 LCB, LCC

Stainless Steel: ASTM A351 CF8, CF8M, CF3M, CF8C

» End Connections: Butt Welded (BW), Flanged (RF, RTJ)

» Standards:

Design and Manufacture: ASME B16.34

Face-to-Face (End-to-End): ANSI B16.10

Flanged Connection: ASME B16.5

Butt Welded End: ANSI B16.25

Testing and Inspection: API 598

» Suitable Mediums: Water, gas, oil, and more

Product Features

» Impact-Free Sealing: The valve closes gently without impact or noise, enhancing durability.

» Enhanced Sealing: Micro-elastic metal seats provide reliable sealing performance.

» Efficient Design: The butterfly disc design enables quick opening and closing with an extended service life.

» Energy Efficiency: The tilting disc structure creates a streamlined fluid passage, reducing flow resistance and saving energy.

Send your message to this supplier

FAQs

OS&Y stands for Outside Screw and Yoke. This design places the threaded stem outside the valve body, with the yoke supporting the stem. It allows users to visually verify whether the valve is open or closed by observing the stem’s position.

OS&Y gate valves are commonly used in fire protection systems, including sprinklers, hydrants, and standpipes, due to their reliability and clear open/close indication.