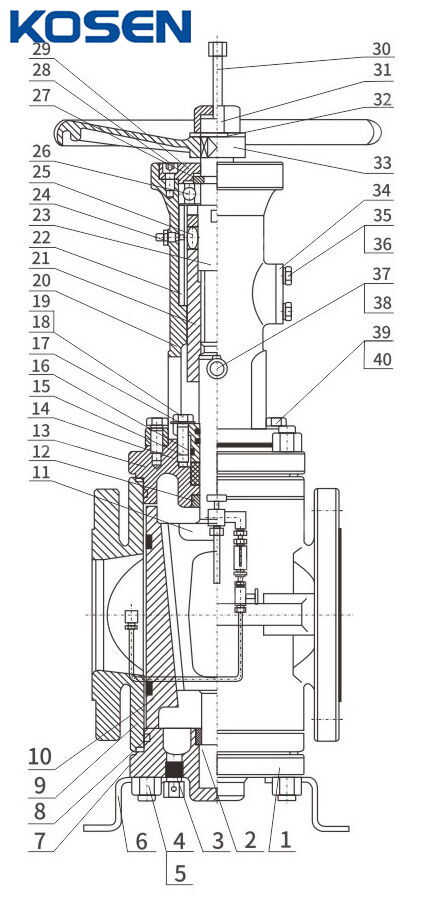

DBB Orbit Plug Valve, API 6D, ASTM A216 WCB, 10 IN, CL300

Key Specifications / Features

Detail Information

Product Name: DBB Twin Seal Orbit Plug Valve

Design Standard: API 6D

Body Material: ASTM A216 WCB

Size: 10 Inch, DN250

Pressure: Class 300 LB, PN50

End Connection: RF

When the twin seal orbit plug valve is fully open, the plug channel aligns with the valve body's channel, ensuring the ideal minimum pressure. Rotating the handwheel moves the plug towards the valve, causing the valve disc to rotate 90 degrees. As the handwheel continues to turn, the plug presses down, closing the valve tightly by pressing the valve disc against the valve seat. Rotating the handwheel in the opposite direction first lifts the plug, releasing the valve disc from the seat. Continuing to turn the handwheel rotates the valve disc 90 degrees, aligning the plug channel with the valve body channel, and the valve returns to its fully open position.

Technical Specification

» Structure: Twin Seal Orbit Plug Valve

» Nominal Diameter: NPS 2–36 Inch (DN50–DN900)

» Design Pressure: Class 150–900 LB (PN20-PN150)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» Design Standard: API 6D, API 599

» Face to Face: ASME B16.10

» Connection Ends: RF, RTJ

» Test Standard: API 598, ISO 5208

» Design Temperature: -46°C to +300°C

» Applicable Medium: Water, Steam, Oil, Gas, etc.

» Operation: Lever, Gear Box, Electric, Pneumatic, Hydraulic

Product Features

This valve is designed with a strong structure, reliable sealing, great performance, and a sleek appearance. The sealing is achieved using rings around the valve disc, with extra protection from the wallow-tailed sink and fixed sealing rings. Its double-direction flow makes installation and use easier. The materials and flange sizes can be customized to match specific needs or customer requirements, making it suitable for various engineering applications.

Send your message to this supplier

FAQs

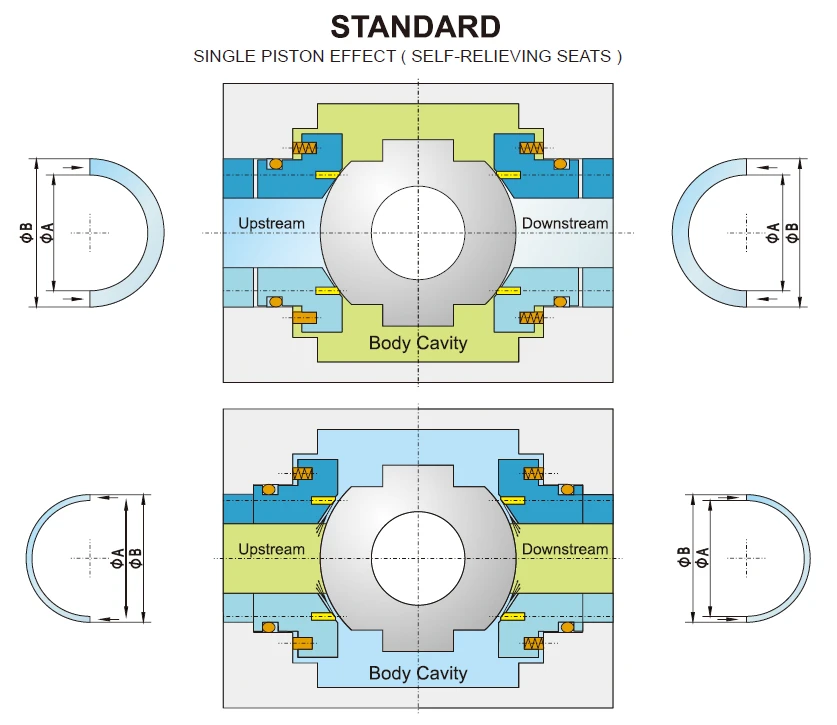

DBB (Double Block and Bleed): Two single piston-effect seats.

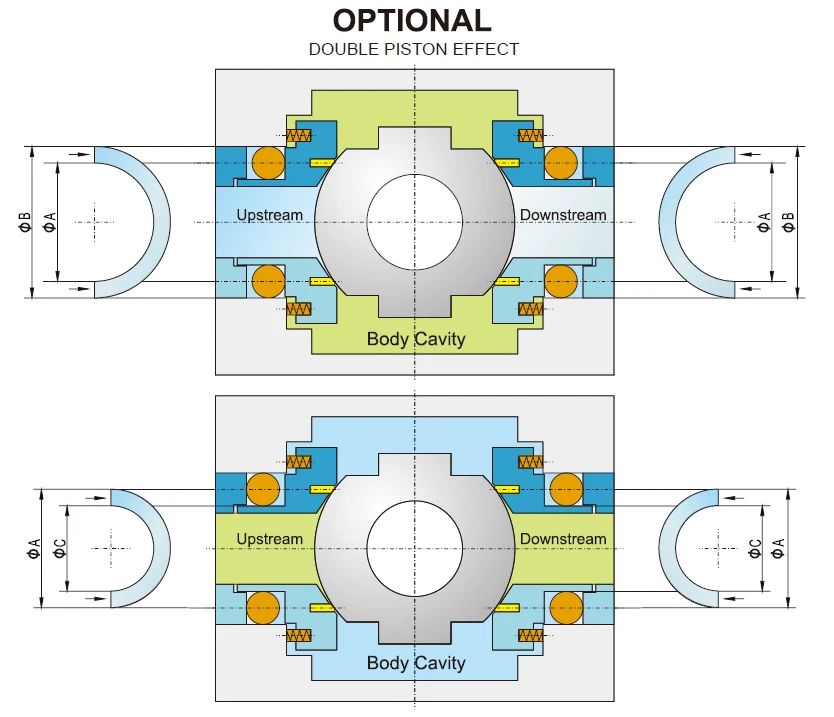

DIB-I (Double Isolation and Bleed Type I): Two double piston-effect seats.

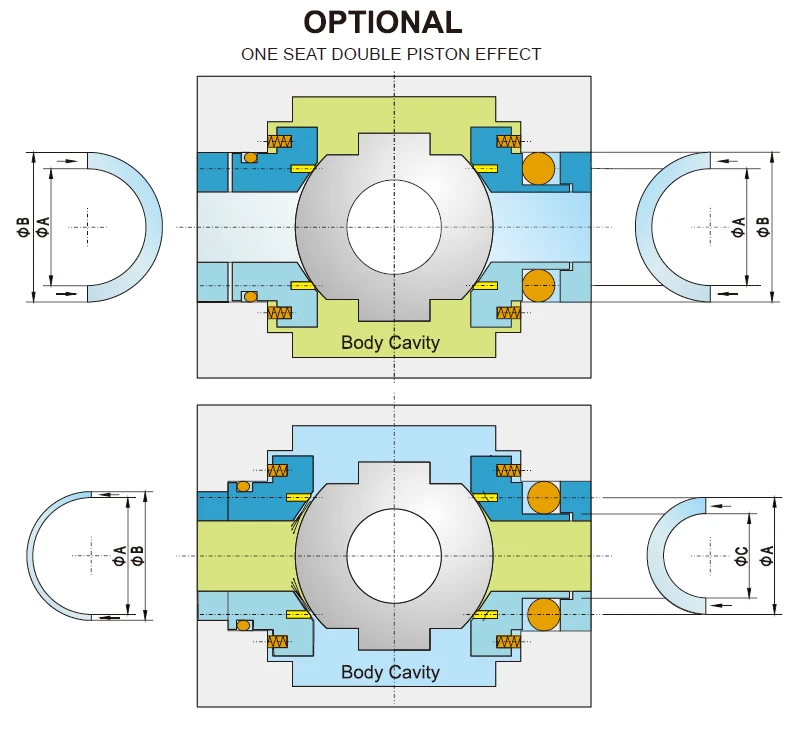

DIB-II (Double Isolation and Bleed Type II): One double piston-effect seat and one single piston-effect seat.