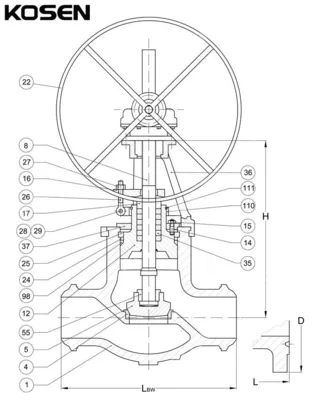

ASTM A216 WCB Globe Valve, BS 1873, 5 Inch, 2500 LB, PSB, BW

Key Specifications / Features

Detail Information

Product Name: ASTM A216 WCB Globe Valve, Pressure Seal Bonnet

Design Standard: BS 1873, ASME B16.34

Body Material: ASTM A216 WCB

Size: 5 Inch, DN125

Pressure: Class 2500 LB, PN420

End Connection: BW

Operation: Handwheel

The Pressure Seal Globe Valves are designed to meet the rigorous demands of high-temperature and high-pressure applications, commonly used in fossil fuel power plants. Built in accordance with BS1873 and ASME B16.34 standards, these valves offer reliable, long-lasting performance, especially in services where traditional bolted bonnet valves may struggle to maintain a reliable seal. The pressure seal design ensures an efficient and compact valve structure, reducing maintenance costs and enhancing operational reliability in high-pressure and high-temperature environments.

The valve's two openings allow for medium flow in the same direction, with a 180° angle, optimizing flow characteristics. The seat and disc sealing surfaces are coated with iron-base, cobalt-base, or carbide alloys, ensuring durability and extended service life. For larger valve sizes, the main and vice disc design reduces operational torque, improving seat tightness and reliability.

Technical Specifications

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: Class 600-2500 LB (PN10-PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, A351 CF8, CF8M, CF3, CF3M

» End Connections: RF, RTJ, BW

» Temperature Range: -29°C to 595°C

» Medium: Water, Gas, Oil, etc.

» Design and Manufacture: ANSI B16.34, BS 1873

» Face to Face (End to End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Butt Welded End: ANSI B16.25

» Test and Inspection: API 598

» Key Features:

A. Back-Up Ring: Absorbs thrust applied by internal pressure, ensuring the integrity of the sealing system.

B. Thrust Ring: Protects the soft metallic gasket from deformation, extending service life.

C. Gasket: The unique angular design provides superior sealing, enhancing valve performance.

Product Features

» Short Stroke for Quick Open/Close: Designed for rapid operation, enabling quick valve actuation.

» Relief Cone for Large Sizes and High Pressure: Featuring an internal bypass, effectively managing pressure relief.

» Disc Sealing Options: Available with flat sealing or throttle cone, offering versatile regulating capabilities.

» Body Seat Options: Can be equipped with a threaded seat or welded seat, depending on application needs.

» Full Stellite Overlay Seat Sealing Surface: Ensuring a durable and reliable sealing surface for long-term performance.

» Easy Manufacturing and Maintenance: Designed for efficient production and straightforward maintenance, minimizing downtime.

» Back Seat Sealing Structure: Incorporating a back seat design, enhancing safety and reliability.

» Flexible and Woven Graphite Packing: Using high-quality packing materials for enhanced sealing performance.

» Reduced Port: Optimizing flow control by minimizing port size, suitable for specific process requirements.