ASME B16.34 Globe Valve, ASTM A216 WCB, 12 IN, 900 LB, PSB

Key Specifications / Features

Detail Information

Product Name: ASME B16.34 Globe Valve

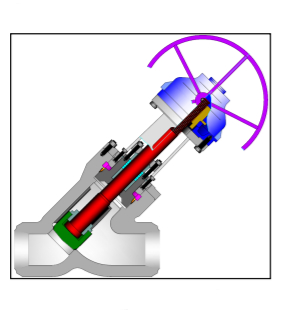

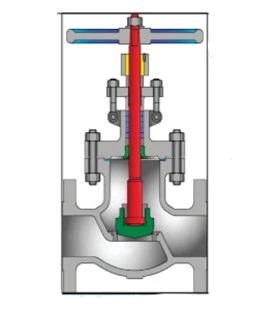

Features: Reduce Port, Pressure Seal Bonnet(PSB)

Design Standard: BS 1873, ASME B16.34

Body Material: ASTM A216 WCB

Size: 12 Inch, DN300

Pressure: Class 900 LB, PN150

End Connection: Flanged

Operation: Manual

The pressure seal globe valves are meticulously engineered in accordance with BS1873 and ASME B16.34 standards for high-temperature and high-pressure service. These valves are commonly used in fossil fuel power plants. Unlike bolted bonnet joint valves, pressure seal valves offer reliable and secure sealing at the bonnet joint, resulting in a more compact and rigid design with lower maintenance costs in high-temperature, high-pressure applications.

The two medium flow openings are aligned in the same direction at a 180° angle, optimizing the flow path. Both the seat and disc sealing surfaces are overlaid with iron-based alloy, cobalt-based alloy, or carbide alloy to extend service life. For larger valves, a main disc and vice disc configuration is employed, with medium flowing from the upper disc to the lower disc, significantly reducing operational torque and enhancing seat tightness reliability.

Technical Specifications

» Nominal Diameter: NPS 2–24 Inch (DN50–DN600)

» Design Pressure: Class 600–2500 LB (PN10–PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, A351 CF8, CF8M, CF3, CF3M, A352 LCB

» Temperature Range: -29°C to 595°C

» Medium: Water, Gas, Oil, and other Fluids

» End Connection: RF, RTJ, BW

» Design and Manufacture: ANSI B16.34, BS 1873

» Face to Face (End to End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Butt Welded End: ANSI B16.25

» Test and Inspection: API 598

» Key Components:

A. Backup Ring: Absorbs internal pressure-induced thrust

B. Thrust Ring: Protects the soft metallic gasket from deformation

C. Gasket: Unique angular design for superior sealing

Product Features

» Short Stroke: Allows for quick and easy open/close operation.

» High Pressure and Large Size: Features a relief cone for internal bypass.

» Disc Sealing Options: Can include flat sealing or throttle cone for regulating discs.

» Body Seat Options: Available in threaded or welded seat designs.

» Stellite Overlay: Full stellite overlay on the seat sealing surface for durability.

» Ease of Manufacture and Maintenance: Designed for efficiency and low maintenance requirements.

» Back Seat Sealing Structure: Ensures a secure seal during operation.

» Packing: Utilizes flexible and woven graphite packing for superior sealing.

» Reduce Port: Optimized for reduced port flow control.