ASTM A216 WCB Globe Valves, ASME B16.34, 6 IN, CL1500, RTJ

Key Specifications / Features

Detail Information

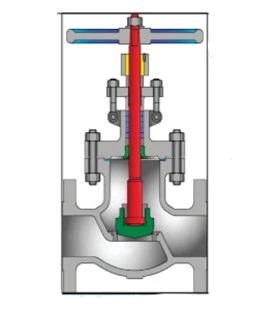

Product Name: Cast Steel Globe Valve

Features: OS&Y, Bolted Bonnet, Rising Stem

Design Standard: ASME B16.34

Body Material: ASTM A216 WCB

Size: 6 Inch, DN150

Pressure: Class 1500 LB, PN250

End Connection: RTJ

Operation: Bevel Gear

Cast Steel Globe Valves are meticulously designed and manufactured to ensure minimal leakage of volatile organic compounds (VOCs), with a maximum of 100 parts per million (ppm). Extensive baseline laboratory testing, including both static and cycle testing, has been conducted to establish critical design parameters. These parameters are essential for achieving low-emission sealing in the stem packing seal area and the bonnet gasket sealing area.

To maintain consistent quality, an in-house testing procedure has been developed and is periodically performed. This ensures that our standard product design and manufacturing criteria consistently result in Cast Steel Globe Valves meeting the maximum VOC leakage limit of 100 ppm prior to shipment.

Technical Specifications

» Nominal Diameter: NPS 1/2–24 Inch (DN15–DN600)

» Design Pressure: Class 150–2500 LB (PN10–PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C, CN3MN, CK3MCUN, CN7M, A890 4A (CD3MN), 5A (CE3MN), 6A (CD3MWCuN), B148 C95800, C95500

» End Connections: Flanged (FF, RF, RTJ) and BW to international standards

» Operation: Handwheel, bevel gear, electric, pneumatic

» Applications: Electric power, petroleum refining, petrochemical engineering, offshore oil, urban water engineering, chemical engineering

» Design and Manufacture: ASME B16.34, BS 1873, DIN 3356

» Face to Face (End to End): ANSI B16.10, EN 558 series

» Flanged Connection: ANSI B16.5, EN 1092 series

» Butt Welded End: ANSI B16.25

» Test and Inspection: API 598, ISO 5208, EN 12266-1

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, and other fluids

Product Features

» Bolted bonnet

» Rising stem

» Short stroke for easy and quick open/close

» For large size and high pressure: relief cone = internal bypass

» Disc sealing options: flat sealing, throttle cone = regulating disc

» Body seat options: threaded seat or welded seat

» OS&Y (Outside Stem and Yoke)

» Metal-sealed (API Trim #1, #5, #8, #10, etc.)

» Optional locking device or stem extension

» Optional direct mounting to ISO 5211

» Reduced port