Orbit Plug Valves: Structure, Performance & Best Practices

Across a wide range of industrial sectors, piping systems are indispensable components, and valves, serving as critical control elements within these systems, play a decisive role in ensuring overall safety, stability, and efficient operation. Among the many types of valves available, the orbit plug valve stands out due to its unique structural design and outstanding performance. Thanks to these advantages, orbit plug valves are widely used in complex and demanding operating conditions, providing reliable and effective fluid control solutions for industrial production.

Basic Structure of Orbit Plug Valves

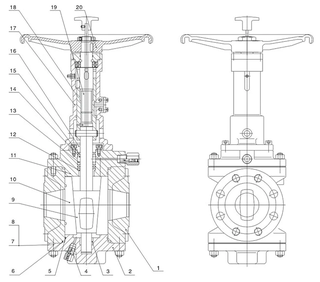

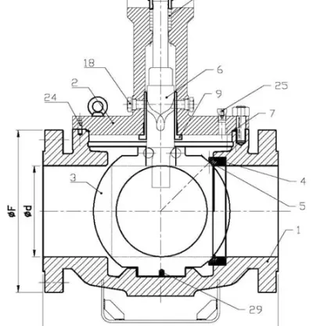

An orbit plug valve is primarily composed of a valve body, orbit mechanism, bearings, and sealing rings. The valve body serves as the main structural framework of the valve and houses a rotatable internal component known as the plug. The plug is the core element of the orbit plug valve and is typically conical or cylindrical in shape, allowing it to rotate smoothly within the valve body.

Bearings connect the plug to the valve body and ensure stable, smooth rotation during operation. Sealing rings are installed at the contact interfaces between the plug and the valve body, playing a crucial role in preventing fluid leakage and maintaining tight shutoff performance.

Working Principle of Orbit Plug Valves

The operating principle of an orbit plug valve is relatively straightforward and intuitive. Through a driving mechanism, such as a manual handle, worm gear, electric actuator, or other actuating devices, the plug rotates inside the valve body. As the plug rotates to specific positions, the opening degree of the valve passage changes accordingly, thereby regulating the flow of fluid within the pipeline.

When the plug rotates to the fully closed position, it fits tightly against the valve body, completely blocking the flow path and achieving shutoff control. When the plug rotates to the fully open position, the flow passage is fully aligned, allowing the fluid to pass through the valve smoothly and unobstructed. This rotary control mechanism provides orbit plug valves with high operational flexibility and fast response during opening and closing.

Performance Advantages of Orbit Plug Valves

The popularity of orbit plug valves among various valve types is mainly attributed to a series of significant performance advantages.

1. Simple Structure and Easy Maintenance

Orbit plug valves feature a simple and straightforward structural design, with few complex components and minimal connection points. This simplicity not only reduces manufacturing costs but also makes daily operation and maintenance much more convenient. Maintenance personnel can easily inspect, clean, and replace components, significantly reducing downtime and maintenance expenses.

For example, when a sealing ring becomes worn or damaged, it can be removed directly from the contact area between the plug and the valve body and replaced with a new one, without requiring complicated disassembly or reassembly of the entire valve.

2. Excellent Sealing Performance

Outstanding sealing performance is one of the core strengths of orbit plug valves. The contact area between the valve body and the orbit mechanism is relatively large. During valve rotation, a certain level of mechanical force is generated between these components, which effectively enhances the sealing performance of the sealing rings.

As a result, orbit plug valves can achieve tight shutoff and reliably prevent fluid leakage in the closed position. Even under challenging conditions involving high temperature, high pressure, high viscosity, or highly corrosive media, orbit plug valves maintain excellent sealing performance, providing strong assurance for safe industrial operation.

3. Low Flow Resistance and High Energy Efficiency

When fluid passes through a valve in a pipeline system, resistance inevitably occurs, reducing transmission efficiency and increasing energy consumption. Due to their unique structural design, orbit plug valves generate relatively low flow resistance.

When the valve is fully open, the plug passage is perfectly aligned with the valve body passage, allowing fluid to pass through with minimal obstruction and almost no additional pressure drop. This low-resistance characteristic not only improves fluid transmission efficiency but also significantly reduces system energy consumption, delivering notable economic benefits in industrial applications.

4. Long Service Life and High Reliability

Orbit plug valves are known for their long service life, largely due to their robust design and careful material selection. Key components such as the valve body and plug are typically manufactured from high-quality materials with excellent corrosion and wear resistance. In addition, special surface treatments, such as hard chrome plating on the valve body interior or nickel plating on the plug, are often applied to further enhance durability.

During operation, the friction between the plug and valve body is relatively low, which reduces wear and prolongs component life. With proper use and routine maintenance, orbit plug valves can maintain stable and reliable performance over extended periods, offering dependable fluid control for industrial systems.

Application Fields of Orbit Plug Valves

Thanks to these performance advantages, orbit plug valves are widely used across numerous industrial sectors to meet diverse fluid control requirements.

1. Petroleum Industry

In oil extraction, transportation, and refining processes, orbit plug valves play a vital role. Petroleum pipeline systems often handle high-temperature, high-pressure, flammable, and explosive media. The excellent sealing performance and corrosion resistance of orbit plug valves make them an ideal choice.

For instance, in oilfield production, orbit plug valves are used to control well output and ensure stable production. In crude oil transmission pipelines, they enable precise flow regulation for efficient transportation. In refineries, orbit plug valves control the flow of various petroleum products and chemical feedstocks, meeting complex process requirements.

2. Chemical Industry

Chemical production involves a wide range of complex media, many of which are highly corrosive or toxic. This places strict demands on valve corrosion resistance and sealing performance. Orbit plug valves, with their corrosion-resistant materials and reliable sealing, effectively prevent leakage and ensure safe chemical processing.

For example, in chlor-alkali production, orbit plug valves are used to control hazardous gases such as chlorine and hydrogen. In fine chemical processes, they regulate the flow of organic solvents and chemical reagents to meet different reaction requirements.

3. Metallurgical Industry

The metallurgical industry presents harsh operating environments characterized by high temperatures, high pressures, and heavy dust. The simple structure, wear resistance, and high-temperature tolerance of orbit plug valves allow them to operate reliably in such conditions.

In steelmaking, orbit plug valves are used in blast furnace gas pipelines and oxygen supply systems to control gas flow and pressure, ensuring stable furnace operation. In non-ferrous metal smelting, they are employed to control corrosive media such as acids and alkalis, meeting stringent process demands.

4. Power Industry

Power plants and substations contain extensive piping systems for transporting cooling water, steam, and fuel oil. Orbit plug valves are used in these systems for both flow regulation and shutoff control.

For example, in thermal power plants, orbit plug valves regulate boiler feedwater flow to ensure stable boiler operation. In generator cooling water systems, they control cooling water flow to maintain proper heat dissipation and safe equipment operation.

Key Considerations for Orbit Plug Valve Selection

When selecting an orbit plug valve, it is essential to consider the actual operating conditions, including fluid properties, working pressure, and operating temperature. For corrosive media, valve bodies and plugs made of corrosion-resistant materials, such as stainless steel or alloy steel, should be selected. For high-pressure applications, valves rated for the corresponding pressure class must be used.

Additionally, the operation method should be chosen based on convenience and automation requirements, whether manual, electric, or pneumatic. Valve size selection is also critical to ensure proper matching with the pipeline diameter and optimal system performance.

Installation Precautions for Orbit Plug Valves

During installation, it is crucial to ensure the valve is positioned correctly, with the inlet and outlet aligned with the pipeline flow direction to avoid operational issues. Care should be taken to protect sealing surfaces and sealing rings during installation to prevent damage.

Connections between the valve and the pipeline must be secure and properly sealed to prevent leakage. For valves that require frequent operation, sufficient space should be reserved around the handle or actuator to facilitate operation and maintenance.

Maintenance of Orbit Plug Valves

Regular maintenance is essential to ensure the long-term, stable operation of orbit plug valves.

- Routine Inspection: Periodically inspect the valve’s exterior for signs of damage, corrosion, or leakage. Check whether the handle or actuator operates smoothly and reliably. Observe changes in pressure and flow during valve operation to detect abnormalities early.

- Cleaning and Lubrication: Regularly clean both external and internal valve surfaces to remove dirt, debris, and dust. Pay particular attention to the plug and valve body surfaces to prevent contaminants from affecting sealing performance. Lubricate moving parts such as bearings and threaded components to ensure smooth operation and reduce wear.

- Inspection and Replacement of Sealing Components: Sealing rings are critical components that directly affect valve tightness. Inspect them regularly for wear, aging, or damage, and replace them promptly when necessary. Follow proper procedures during replacement to ensure correct installation and restored sealing performance.

- Valve Adjustment and Calibration: For orbit plug valves equipped with actuators, regular adjustment and calibration are required to ensure accurate correspondence between actuator movement and valve position. Proper calibration ensures precise control in automated systems and reliable process performance.

Conclusion

As a high-performance industrial valve, the orbit plug valve demonstrates unique advantages and broad application value across many industries. Its simple structure, excellent sealing performance, low flow resistance, and long service life enable it to meet stringent fluid control requirements under complex operating conditions. By following proper selection, installation, maintenance, and servicing practices, orbit plug valves can deliver stable, long-term operation and reliable protection for industrial systems. With continuous advancements in industrial technology, the performance and functionality of orbit plug valves will continue to improve, expanding their application scope and contributing even more significantly to the future of industrial development.

Send your message to this supplier

Related Articles from the Supplier

An Introduction to Orbit Ball Valve

- Nov 26, 2025

Related Articles from China Manufacturers

What You Should Know about Orbit Ball Valves?

- Feb 13, 2024

Maintenance and Care of Orbit Ball Valves

- Jul 26, 2024

New Hydrogenated High Pressure Orbit Ball Valves

- Sep 15, 2017

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/orbit-plug-valves-structure-performance-best-practices.html