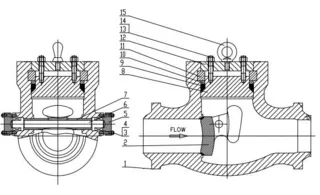

Tilting Disc Check Valve, ASME B16.34, LCC, 8 Inch, 2500 LB

Key Specifications / Features

The Tilting Disc Check Valve manufactured in China is a high-performance solution designed for critical industrial applications. It adheres to ASME B16.34 standards and features a cast carbon steel body made from ASTM A352 LCC material, ensuring robustness and durability. With an 8-inch (DN200) size and a high-pressure rating of 2500 LB (PN420), this valve is built to handle demanding conditions. The raised face (RF) ends provide secure and reliable connections, making it an ideal choice for systems requiring precise flow control and backflow prevention.

Detail Information

Product Name: Tilting Disc Check Valve

Design Standard: ASME B16.34

Body Material: ASTM A352 LCC

Size: 8 Inch, DN200

Pressure Rating: Class 2500 LB, PN420

End Connection: RF Flanged

Medium: Oil, Gas, Water, Steam, etc

Temperature Range: -196°C to 450°C

Standards

Design & Manufacturing: ASME B16.34

Test & Inspection: API 598

Face to Face: ASME B16.10

Flanged End: ASME B16.5

A tilting disc check valve operates based on pressure differential, enabling automatic function without the need for an actuator, handwheel, or lever. The valve opens when the inlet (suction) pressure exceeds the outlet pressure by a sufficient margin, generating enough force to tilt the disc away from the seat. This pressure is typically supplied by the pump in the piping system. Once opened, fluid continues to flow through the valve as long as the inlet pressure remains higher than the outlet pressure. If the suction pressure drops below the outlet pressure or if backflow occurs, the disc automatically returns to the closed (seated) position.

To enhance responsiveness, manufacturers often incorporate a spring mechanism to assist the disc in closing immediately when fluid pressure decreases. Tilting disc check valves are versatile and can be installed in both vertical and horizontal orientations.