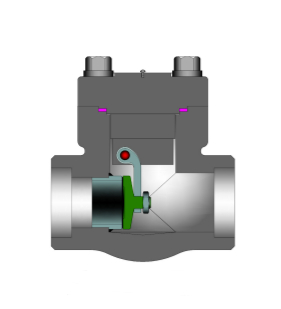

API 602 Check Valve

Key Specifications / Features

API 602 Check Valve Manufacturer in China: API 602 Check Valve, ASTM A105, LF2, 1/2 Inch - 2 Inch, CL150 - CL2500, API 602, BS 5352, ASME B16.34.

Request a quote

Detail Information

Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate. Topper manufactures and supplies check valves that boast superior quality and meet the standard of API 602.

Product Details:

Design standard: API 602, BS 5352.

The length of the structure: Factory standard, ASME B16.10, GB/T 12221.

Flange connecting end: ASME B16.5, GB/T 9113, HG/T 20592, EN 1092.1.

Butt welding connecting end: ASME B16.25, GB/T 12224.

Wall thickness: API 602, ASME B16.34, GB/T 12224.

Inspection and test: API 602, GB/T 13927.

Pressure and temperature rating: ASME B16.34, EN 12516, GB/T 12224.

Product scope: NPS ½ Inch - NPS 2 Inch (DN15 - DN50), CL150 - CL2500 (PN16 - PN420).

Main body material: ASTM A105, ASTM A350 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

Product Details:

Design standard: API 602, BS 5352.

The length of the structure: Factory standard, ASME B16.10, GB/T 12221.

Flange connecting end: ASME B16.5, GB/T 9113, HG/T 20592, EN 1092.1.

Butt welding connecting end: ASME B16.25, GB/T 12224.

Wall thickness: API 602, ASME B16.34, GB/T 12224.

Inspection and test: API 602, GB/T 13927.

Pressure and temperature rating: ASME B16.34, EN 12516, GB/T 12224.

Product scope: NPS ½ Inch - NPS 2 Inch (DN15 - DN50), CL150 - CL2500 (PN16 - PN420).

Main body material: ASTM A105, ASTM A350 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.