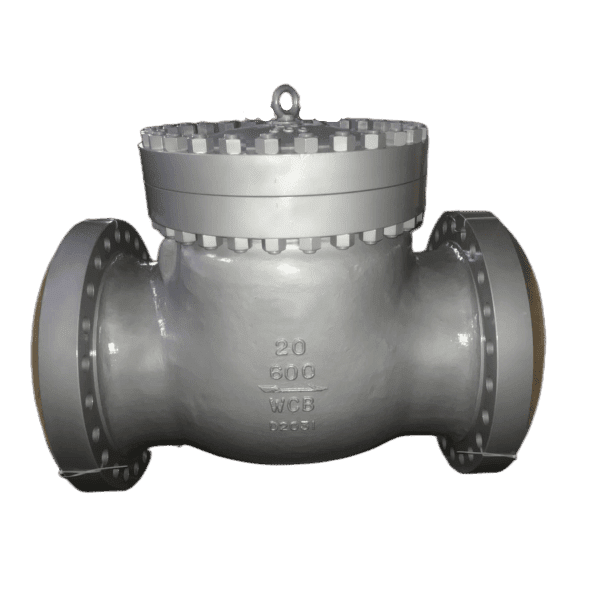

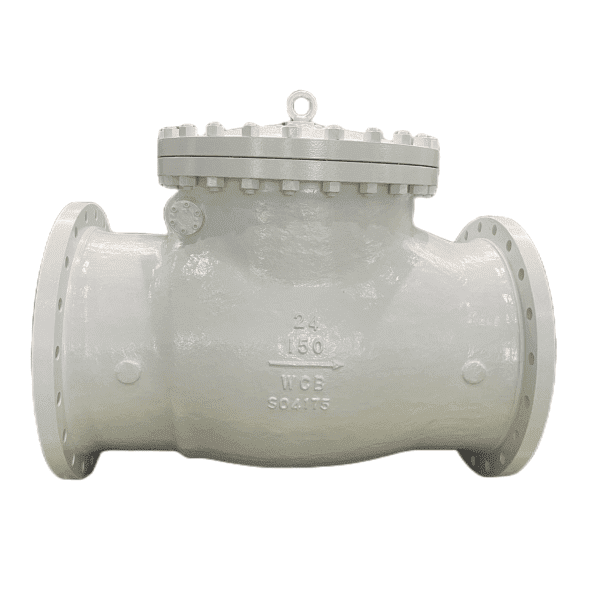

API 594 Check Valve

Key Specifications / Features

API 594 Check Valve Manufacturer in China: API 594 Check Valve, ASTM A216 WCB, ASTM A352 LCB, 1/2 Inch - 36 Inch, CL150 - CL2500, API 594, ASME B16.34.

Request a quote

Detail Information

Design standard: API 594.

Length of structure: API 594.

Pipe flange: ASME B16.5.

Wall thickness: ASME B16.34.

Inspection and test: API 598.

Pressure and temperature rating: ASME B16.34.

Product scope: NPS 1/2 Inch - NPS 36 Inch, CL150 - CL2500.

Main body material: ASTM A216 WCB, ASTM A352 LCB, ASTM A216 WCC, ASTM A217 WC6, ASTM A217 WC9, ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3, ASTM A351 CF3M, ASTM A890 4A, ASTM A105, ASTM A350 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

API 594 check valves that Topper provides have center vertical pin shafts. When the valve is open, the resultant force of fluid is on the center of the sealing face of valve clack, while the point of the action of counter spring supporting force is on the center of valve clack surface so that the root of valve clack opens firstly. It avoids wearing of sealing face of old conventional valve when valve opens, and increases the persistence of valve seal. When flow slows down, counter force of torsion spring makes the valve clack move to valve seat, and the valve is in slowing off stage. When fluid flows backwards, the closing of valve clack is correspondingly increased and enters the rapid closing stage under the force of backflow fluid on valve clack and counterforce of torsion spring. The influence and harm of water hammers are effectively reduced. When closed, the spring force closes the top of valve clack firstly so that bite phenomenon on root of valve clack is prevented to guarantee longer service life of valve sealing face. API 594 single clack wafer check valves are single clack swing wafer connecting check valves that prevent backflow of mediums. They are all ultra-thin check valves. Single clack swing wafer connecting check valves are designed to be connected through wafer, stainless steel or stellite build up welding may be applied to the sealing face of valve body and valve clack. These valves are suitable for cleaning mediumd, but not suitable for mediums with solid particles and great viscosity. One of the main advantages of tilting disc check valves is that they can overcome shock, water hammer in operating condition of swing check valve and lifting check valve to realize shock-free operation.

Length of structure: API 594.

Pipe flange: ASME B16.5.

Wall thickness: ASME B16.34.

Inspection and test: API 598.

Pressure and temperature rating: ASME B16.34.

Product scope: NPS 1/2 Inch - NPS 36 Inch, CL150 - CL2500.

Main body material: ASTM A216 WCB, ASTM A352 LCB, ASTM A216 WCC, ASTM A217 WC6, ASTM A217 WC9, ASTM A351 CF8, ASTM A351 CF8M, ASTM A351 CF3, ASTM A351 CF3M, ASTM A890 4A, ASTM A105, ASTM A350 LF2, ASTM A182 F11, ASTM A182 F22, ASTM A182 F51, ASTM A182 F91, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304L, ASTM A182 F316L, etc.

API 594 check valves that Topper provides have center vertical pin shafts. When the valve is open, the resultant force of fluid is on the center of the sealing face of valve clack, while the point of the action of counter spring supporting force is on the center of valve clack surface so that the root of valve clack opens firstly. It avoids wearing of sealing face of old conventional valve when valve opens, and increases the persistence of valve seal. When flow slows down, counter force of torsion spring makes the valve clack move to valve seat, and the valve is in slowing off stage. When fluid flows backwards, the closing of valve clack is correspondingly increased and enters the rapid closing stage under the force of backflow fluid on valve clack and counterforce of torsion spring. The influence and harm of water hammers are effectively reduced. When closed, the spring force closes the top of valve clack firstly so that bite phenomenon on root of valve clack is prevented to guarantee longer service life of valve sealing face. API 594 single clack wafer check valves are single clack swing wafer connecting check valves that prevent backflow of mediums. They are all ultra-thin check valves. Single clack swing wafer connecting check valves are designed to be connected through wafer, stainless steel or stellite build up welding may be applied to the sealing face of valve body and valve clack. These valves are suitable for cleaning mediumd, but not suitable for mediums with solid particles and great viscosity. One of the main advantages of tilting disc check valves is that they can overcome shock, water hammer in operating condition of swing check valve and lifting check valve to realize shock-free operation.