Spring Return Pneumatic Segment Ball Valve, WCB, DN100, PN10

Key Specifications / Features

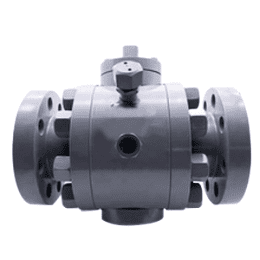

Our Carbon Steel Segment Ball Valve plant specializes in manufacturing high-quality valves using ASTM A216 WCB material, ensuring durability and reliability. These valves are designed with a 4-inch (DN100) size and a PN10 pressure rating, equivalent to Class 150 LB. Equipped with a spring return pneumatic actuator, they offer precise control and automated operation. The valves feature RF flanged ends for secure and leak-tight connections.

Detail Information

Product Name: Pneumatic Segment Ball Valve

Body Material: ASTM A216 WCB

Size: DN100, 4 Inch

Pressure: PN10, Class 150 LB

End Connection: RF

Operation: Spring Return Pneumatic Actuator

The Segment Ball Valve is primarily designed for flow control and can also be used for shut-off operations. The notched port on the segment ball generates strong shear stress, enabling it to cut through media containing fibers and particles. Consequently, this Segment Ball Valve is an excellent general control valve (with an equal percentage flow characteristic) for most pulp and paper process applications, as well as for similar flows containing fibers and particles.

A V-port ball valve features either a V shaped ball or a V shaped seat. This design allows the orifice to be opened and closed in a more controlled manner, resulting in a flow characteristic that is closer to linear. When the valve is in the closed position and begins to open, the small end of the 'V' is opened first, ensuring stable flow control during this stage. Due to the higher velocities of the fluids, which might damage a standard valve, this type of design requires a more robust construction.

Technical Specification

» Size Range: NPS 1–32 Inch (DN25–DN800)

» Design Pressure: Class 150–600 LB (PN10–PN100)

» Body Materials: Cast Carbon Steel, Stainless Steel, Special Alloy (ASTM A216 WCB, WCC, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M)

» Ball/Stem Materials: Stainless Steel, Special Alloy

» Seat Material: Stainless Steel + STL, PCTFE, PEEK

» End Connections: Flanged RF, Wafer

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Design and Manufacture: JB/T 13517-2018

» Face to Face (End to End): ISA S75.04, IEC/DIN 534-3-2 (Flange)

» Flanged Connection: ASME B16.5, GB/T 9113, JB/T 79, HG 20592

» Test and Inspection: DIN 3230, ISO 5208, ANSI/FCI 70-2

» Temperature Range: -29°C to 450°C

» Medium: Pulp & Paper, Water Treatment, Food

Product Features

» Precise V-Notch Design: The finely contoured V-notch ensures exceptional control for a wide range of flow applications.

» Low Maintenance: Easily replaceable seats reduce repair costs and simplify maintenance.

» High Capacity: Heavy-duty construction with an unrestricted straight-through flow path provides superior flow performance.

» Advanced Trunnion Bearings: Engineered for excellent abrasion resistance, ensuring durability in demanding conditions.

» Metal-Seated Option: Rugged, self-adjusting metal seats are ideal for high-temperature applications or handling slurries.

» Reliable Sealing: Features Class V sealing standards for excellent leak prevention.

» Precise Control: The splined connection between the shaft and ball delivers accurate control with minimal hysteresis.

» Non-Clogging Operation: Shearing action between the ball and seal ensures smooth performance, ideal for fibers or slurries.

» Enhanced Sealing: A spring-loaded seat maintains consistent contact with the ball, improving sealing performance over time.