Pneumatic Actuated Pinch Valves, Rubber Sleeve, 1-40 Inch

Key Specifications / Features

Detail Information

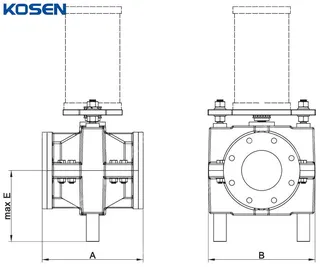

Product Name: Pneumatic Heavy Duty Pinch Valve

Size Range: DN25-DN1000, 1-40 Inch

Pressure: 0.6 MPa/1.0 MPa/1.6 MPa, PN6-PN16

Body Material: Cast Iron/Aluminum Alloy/Carbon Steel/Stainless Steel

Rubber Sleeve Technology: Pure manual import top technology

Rubber Sleeve Materials: High wear-resistant red glue/NR/EPDM, etc.

Temperature: -35°C to +130°C

Flange Standard: PN10/16, ANSI Class 150 LB

Control Conditions: Handwheel, Pneumatic, Electric

Applicable: Sewage, mineral pulp, acid-base media, dry powder, etc.

Operation: Operate the hand wheel to squeeze the internal rubber hose to achieve the opening and closing function

Pinch valves are designed for shut-off or control applications involving abrasive or corrosive slurries, powders, or granular substances. Our advanced flow control solutions are engineered to meet demanding customer specifications, helping improve process efficiency and extend service intervals. The KOSEN pinch valve consists of three main components: the sleeve, the body, and the actuator. The sleeve, being the only part in contact with the process medium, plays a critical role. All three components can be customized to suit a wide range of process conditions. These valves provide a 100% tight shut-off, even in cases where solids have accumulated on the sleeve wall. When compressed, any crystallized particles are dislodged from the sleeve and washed downstream, ensuring reliable operation.

Pinch Valve Advantages

» No pressure loss, blockage, or leakage; highly resistant to impact.

» Ideal for liquid-solid and gas-solid two-phase media containing particles.

» Reinforced with cord fabric for enhanced wear, corrosion, tear, and fatigue resistance.