Electric Actuated Pinch Valve, Cast Iron, DN100, PN10, 4 IN

Key Specifications / Features

Detail Information

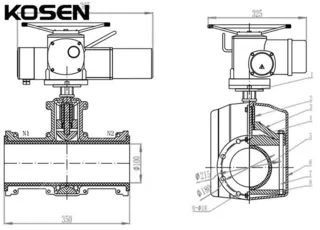

Product Name: Electric Actuated Pinch Valve, Automatic

Body Material: Cast Iron

Sleeve Material: Rubber

Size: DN100, 4 Inch

Pressure: PN10, Class 150 LB

End Connection: Flanged

Operation: Electric Actuator

Pinch valves are ideal for shut-off or control applications involving abrasive or corrosive slurries, powders, or granular substances. Our advanced flow control solutions are designed to meet the most demanding customer specifications. KOSEN valves help improve productivity by enhancing process efficiency and extending service intervals.

The pinch valve design consists of three main components: the sleeve, the body, and the actuator. The sleeve is the only part in contact with the process medium, and the construction and materials of all three components can be customized to suit most process conditions. Our pinch valves provide a 100% tight shut-off, even when solids have built up on the sleeve wall. When compressed, any crystallized particles flake off the sleeve surface and are washed downstream.

Technical Specification

Normal Size Range: 1–16 Inch (DN25–DN400)

Normal Pressure Rating: PN10-PN16, Class 150 LB

Body Materials: Aluminium Alloy, Stainless Steel, GG25, GGG40, ASTM A216 WCB

Sleeve Materials: Natural Rubber, EPDM

Connection: Flanged

Operation: Handwheel, Bevel Gear, Pneumatic, Electric

Temperature Range: -29°C to 85°C

Medium: Slurry, Abrasive, Dust