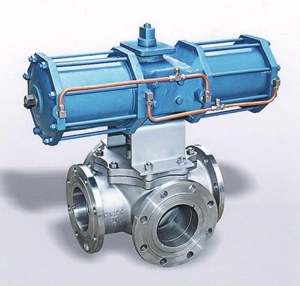

Four-way Plug Valve, API 6D, ASTM B148 C95800, 4 Inch, CL150

Key Specifications / Features

The Four-way Multi-port Plug Valve Plant is designed to meet the stringent standards of API 6D. Constructed from high-quality Aluminum Bronze ASTM B148 C95800, this valve features a 4-inch (DN100) diameter and is rated for Class 150 LB and PN20 pressure classes. It is equipped with FF flanged connections, ensuring secure and reliable installation. The valve is operated via a worm gear mechanism, providing precise control and ease of operation.

Detail Information

Product Name: Four-way Multi-port Plug Valve

Design Standard: API 6D

Body Material: ASTM B148 C95800

Size: 4 Inch, DN100

Pressure: Class 150 LB, PN20

End Connection: FF Flanged

Operation: Worm Gear

The 4-way multiport plug valve is designed to change the direction of medium flow, effectively distributing fluids across multiple channels. Depending on the application, this valve can be customized to accommodate various flow patterns, materials (such as cast iron, cast steel, or stainless steel), and sealing types (e.g., metal-to-metal, sleeve, or lubricated seals). The valve's components, including material selection and flange sizes, can be tailored to meet specific operational requirements, ensuring flexibility to satisfy diverse engineering needs.

Technical Specifications

» Nominal Diameter: NPS 1/2-14 Inch (DN15-DN350)

» Design Pressure: Class 150-900 LB (PN20-PN160)

» Materials:

ASTM A216 WCB, WCC

ASTM A352 LCB, LCC

ASTM A351 CF8, CF8M, CF3M, CF8C, CN3MN, CN7M

ASTM A890 4A (CD3MN), 5A (CE3MN), 6A (CD3MWCuN)

ASTM B148 C95800, C95500

» Design Temperature: -46°C to +120°C

» Medium: Water, gas, oil, etc.

» Design Standard: API 6D, API 599

» Face to Face: ASME B16.10

» Connection End: RF, RTJ, BW

» Test Standard: API 598, ISO 5208

» Operation: Lever, worm gear, electric, pneumatic

» Applications: Petrochemical, chemical, natural gas, LPG, HVAC, food, and pharmaceuticals

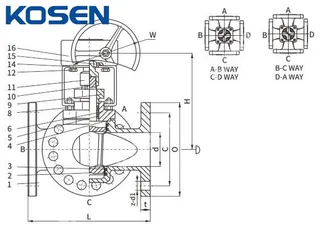

» Function: The 4-way plug valve can be customized to support various media flow configurations, such as "L" or "T" types, depending on the application. It can also feature different sealing options, including metal-to-metal, sleeve-type, or lubricated seals, to suit specific requirements. Notably, the valve design ensures there is no cavity, preventing the accumulation of medium inside the valve.

Material for Main Parts

|

No |

Name of Parts |

Material |

|

1 |

Body |

ASTM B148 C95800 |

|

2 |

Plug |

ASTM B148 C95800 |

|

3 |

Seat |

PTFE |

|

4 |

Gasket |

PTFE |

|

5 |

Packing |

PTFE |

|

6 |

Bonnet |

ASTM B148 C95800 |

|

7 |

Bolt |

ASTM A193 B8M |

|

8 |

Nut |

ASTM A194 8M |

|

9 |

Gland |

ASTM B148 C95800 |

|

10 |

Bolt |

A193 B8M |

|

11 |

Coupling sleeve |

AISI 1045 |

|

12 |

Bolt |

AISI 1035 |

|

13 |

Gasket |

AISI 1035 |

|

14 |

Yoke |

ASTM A283 Grade D |

|

15 |

Pin |

AISI 1045 |

|

16 |

Worm gear |

Ductile Iron |