ASTM A352 LCC Jacketed Plug Valve, API 6D, 20*24 IN, 150 LB

Key Specifications / Features

Detail Information

Product Name: PTFE Sleeved Jacketed Plug Valve

Design Standard: API 6D, API 599

Body Material: ASTM A352 LCC

Size: 20 Inch x 24 Inch, DN500*DN600

Pressure: Class 150 LB, PN20

End Connection: RF Flanged

Operation: Wormgear

The Full Port Steam Jacketed Plug Valve is a versatile valve designed for applications requiring precise control of media with high viscosity or suspended particles. It is available in both lubricated and non-lubricated designs, offering flexibility to meet various operational needs. The valve is ideal for cutting, connecting, and diverting media, and it can also be used for throttling, depending on the application and the erosion resistance of the sealing surface.

The unique design of the valve includes a metal jacket around the valve body, through which steam, heat-conducting oil, cooling water, or cool air is injected. This jacketed design ensures that the media inside the valve is maintained at the required temperature, providing efficient heating or cooling to handle high-viscosity fluids that may solidify at room temperature. The full port design allows for a clear flow path when the valve is fully open, preventing contact between the media and the sealing surface, which extends the life of the valve.

Full port steam jacketed plug valves are primarily used in industries where media at elevated or reduced temperatures must be handled to maintain smooth flow, such as in the processing of viscous liquids, steam, or other temperature-sensitive substances. This valve plays a critical role in ensuring the proper temperature and flow conditions for safe and efficient operation.

Technical Specifications

» Nominal Diameter: NPS 1/2-14 Inch (DN15-DN350)

» Design Pressure: Class 150-900 LB (PN20-PN160)

» Materials:

ASTM A216 WCB, WCC

ASTM A352 LCB, LCC

ASTM A351 CF8, CF8M, CF3M, CF8C, CN3MN, CN7M

ASTM A890 4A (CD3MN), 5A (CE3MN), 6A (CD3MWCuN)

ASTM B148 C95800, C95500

» Design Temperature: -46°C to +120°C

» Medium: Water, gas, oil, etc.

» Design Standard: API 6D, API 599

» Face to Face: ASME B16.10

» Connection End: RF, RTJ, BW

» Test Standard: API 598, ISO 5208

» Operation: Lever, worm gear, electric, pneumatic

» Applications: Petrochemical, chemical, natural gas, LPG, HVAC, food, and pharmaceuticals

» Key Functions

Function 1: Optional bore patterns: Venturi, Regular, Short, Standard

Function 2: Metal-to-metal seated design

Function 3: Injection grease-sealed design (for stem and seats)

Function 4: Fire-safe design

Function 5: Integral seat ring

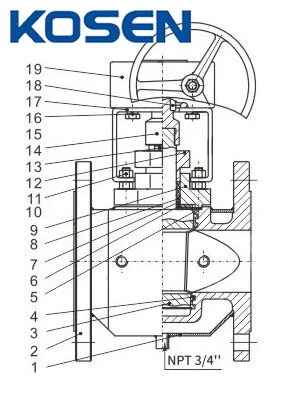

Material for Main Parts

|

No. |

Name of Parts |

Material |

|

1 |

Jacket |

ASTM A283 Grade D, SS 304, SS 316 |

|

2 |

Body |

ASTM A216 WCB, A351 CF8, CF8M, CF3M, CN7M, SS 904L |

|

3 |

Plug |

ASTM A351 CF8, CF8M, CF3M, CN7M, SS 904L |

|

4 |

Seat |

PTFE, RPTFE, PPL, NYLON, PEEK |

|

5 |

Gasket |

PTFE, RPTFE, PPL, NYLON, PEEK, Graphite + SS |

|

6 |

Packing Pad |

SS 304, SS 316, SS 316L |

|

7 |

Packing Pad |

SS 304, SS 316, SS 316L |

|

8 |

Packing |

Graphite, PTFE, RPTFE, PPL |

|

9 |

Bonnet |

ASTM A216 WCB, A351 CF8, CF8M, CF3M, CN7M, SS 904L |

|

10 |

Bolt |

B7, B7M, B8, B8M |

|

11 |

Nut |

2H, 2HM, 8, 8M |