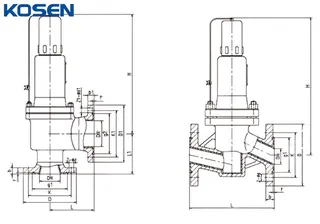

Fluorine Lined Safety Valve, API 526, A216 WCB, DN50 x DN80

Key Specifications / Features

Detail Information

Product Name: Fluorine Lined Safety Valve, Bellows Sealed

Standard: API 526

Body Material: ASTM A216 WCB

Lining: Fluorine Lined

Size: DN50 x DN80, 2 Inch x 3 Inch

Pressure: PN16, Class 150 LB

End Connection: RF Flanged

The Fluorine Lined Safety Valve is designed primarily for high-pressure equipment handling highly corrosive media, such as those in the chlor-alkali chemical industry and hydrochloric acid applications. This safety valve is used in pressure vessels and automatic pressure release devices on pipelines, offering exceptional resistance to corrosion. Critical components are fully lined with tetrafluoroethylene (PFA, FEP) material, ensuring resistance to hydrochloric acid and other aggressive chemicals. The valve body undergoes chemical treatment through ion pulse nitriding or is lined with Teflon to enhance its corrosion resistance. It features dual seals comprising corrosion-resistant fluorine bellows and a fluorine rubber O-ring to effectively prevent external leakage. This valve fully complies with national sealing performance standards, making it a reliable replacement in applications involving hydrochloric acid, sulfuric acid, and other corrosive chemicals. The valve's internal components, including the valve body, core, disc, and stem, are lined with PFA or FEP materials, providing robust protection against corrosive environments.

Technical Specifications

Normal Size Range: 1-8 Inch (DN25-DN200)

Normal Pressure Rating: PN10, PN16, Class 150 LB

Design and Manufacture: GB/T 12243-1989, API RP 520, 521, API 526, API 527

Face to Face (End to End): GB/T 14087, JB/T 6441, JB/T 2203, JB/T 9624, JB/T 53170

Flanged Connection: ASME B16.5, DIN 2543-2545, EN 12627

Test and Inspection: API 598, DIN 3230, MSS SP-117

Materials: Carbon Steel, Stainless Steel, Alloy Steel, Duplex or Other Specials

Working Medium: Hydrochloric acid, strong corrosive media

Ends Connections: RF Flanged