ASTM A351 CF8 Safety Valve, API 526, 2 Inch, 150 LB, Flanged

Key Specifications / Features

The ASTM A351 CF8 Safety Valve is a spring full lift type with a stainless steel body. It has a 2-inch (DN50) size, Class 150 LB, and PN16 pressure rating. Featuring flanged end connections and complying with API 526 standards, this valve ensures reliable pressure relief in industrial systems.

Detail Information

Product Name: ASTM A351 CF8 Safety Valve

Type: Spring Full Lift Safety Valve

Design Standard: API 526

Body Material: ASTM A351 CF8

Size: DN50, 2 Inch

Pressure: PN16, Class 150 LB

End Connection: Flanged

The Spring Full Lift Safety Valve is designed for systems with simple discharge conditions. It can handle discharge pressures that are atmospheric, constant, or may increase by up to 10% of the set pressure. In systems with constant back pressure, the valve should be set according to the differential pressure. The valve disc has two types of sealing surfaces: flat and conical. The discharge area is calculated based on the cylindrical or conical surface formed between the valve disc and the valve seat. This valve is ideal for applications with small discharge capacities, large back pressure, and stable system pressure.

Technical Specifications

» Normal Size Range: 1/2-16 Inch (DN15-DN400)

» Normal Pressure Rating: Class 150-600 LB (PN10-PN100)

» Materials: Carbon Steel, Stainless Steel, Alloy Steel, Duplex, or Other Specials

» Design and Manufacture: GB/T 12243-1989, API RP 520, 521, API 526, API 527

» Face to Face (End to End): GB/T 14087, JB/T 6441, JB/T 2203, JB/T 9624, JB/T 53170

» Flanged Connection: ASME B16.5, DIN 2543 to 2545, EN 12627

» Test and Inspection: API 598, DIN 3230, MSS SP-117

» End Connections: Flanged (FF, RF, RTJ) to international standards

» Working Medium: gas, liquid and steam

Product Features

» Lighter and More Compact Construction: Continuous design improvements have led to smaller and lighter valves, aligning with current industry trends focused on saving space and reducing weight.

» Interchangeable Parts: These valves can be easily modified from one type to another (e.g., gas, liquid, conventional, and bellows) by changing only a few parts, providing versatile adaptability.

» Simplified Maintenance and Service: Re-engineering efforts have streamlined the design, reducing the number of parts and making maintenance more straightforward and cost-effective.

» Material Selection: A broad range of materials is available, including non-ferrous materials for low-temperature and oxygen service, as well as exotic alloys tailored for the chemical and process industries.

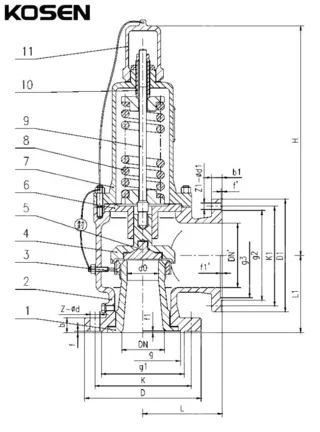

Main Parts and Materials

|

No |

Name of Parts |

Carbon steel |

Stainless steel |

Stainless steel |

|

1 |

Body |

A216 WCB |

A351 CF8 |

A351 CF8M |

|

2 |

Nozzle |

2Cr13, SS 304 |

SS 304 |

SS 316+STL |

|

3 |

Adjusting Ring |

2Cr13, SS 304 |

SS 304 |

SS 316 |

|

4 |

Disc |

2Cr13, SS 304 |

SS 304 |

SS 316 |

|

5 |

Guide |

2Cr13, SS 304 |

SS 304 |

SS 316 |

|

6 |

Bonnet |

ZG230-450 |

SS 304 |

SS 316 |

|

7 |

Spring |

50CrVA |

50CrVA |

50CrVA |

|

8 |

Stem |

2Cr13 |

2Cr13 |

SS 316 |

|

9 |

Adjusting Bolt |

AISI 1045 |

2Cr13 |

SS 316 |

|

10 |

Cap |

ZG230-450 |

SS 304 |

SS 316 |

|

11 |

Sealing surface |

Overlay stellite |

Overlay stellite |

Overlay stellite |