Duplex Spring Safety Valve, API 526, ASTM A216 WCB, DN50, RF

Key Specifications / Features

This Duplex Spring Safety Valve is designed in accordance with API 526 for reliable overpressure protection. It features a robust ASTM A216 WCB carbon steel body, ensuring durability and performance in various industrial settings. With a DN50 (2 inch) size, PN16 / Class 150 LB pressure rating, and RF flanged ends, this valve is ideal for safeguarding pipelines and equipment in oil, gas, and process industries.

Detail Information

Product Name: Duplex Spring Safety Valve

Design Standard: API 526

Body Material: ASTM A216 WCB

Size: DN50, 2 Inch

Pressure: PN16, Class 150 LB

End Connection: RF Flanged

Medium: Steam, Air

The Duplex Spring Safety Valve consists of two safety valves (A47H and A48Y types) of the same specification, installed on a Y-type joint. The nominal diameter of this dual-valve assembly refers to the inlet size of the Y-type connection. As a critical safety device, this valve is designed to prevent pressure equipment or containers from rupturing due to excessive internal pressure or pressure surges, ensuring operational safety and system reliability.

Technical Specification

» Product Model: A38Y

» Normal Size Range: 2-6 Inch (DN50-DN150)

» Pressure Rating: PN16-PN40, Class 150 LB

» Design & Manufacture Standards: GB/T 12243-1989, API RP 520, 521, API 526, API 527

» Face-to-Face (End-to-End): GB/T 14087, JB/T 6441, JB/T 2203, JB/T 9624, JB/T 53170

» Flanged Connection: ASME B16.5, DIN 2543-2545, EN 12627

» Test & Inspection: API 598, DIN 3230, MSS SP-117

» Material Options: Carbon Steel, Stainless Steel, Alloy Steel, Duplex, or Other Specials

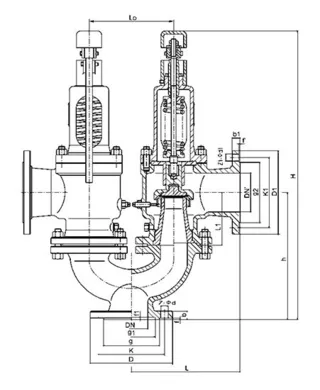

Structural Diagram

Product Features

When the internal pressure of the equipment exceeds the specified working pressure and reaches the opening setpoint of the safety valve, the force exerted by the medium on the valve disc surpasses the opposing force of the loading mechanism. As a result, the valve disc lifts off the seat, causing the safety valve to open and allowing the medium to be discharged through the valve outlet.

If the discharge capacity of the safety valve exceeds the system's required relief volume, the internal pressure of the equipment gradually decreases. After a short discharge period, the pressure returns to the normal working level, and the valve reseats, restoring system equilibrium.