ASTM A352 LCC Gate Valve, API 600, 3 IN, CL300, Rising Stem

Key Specifications / Features

This ASTM A352 LCC Gate Valve is engineered for low-temperature service, manufactured to API 600 standards. Made from low-temp carbon steel, it features a 3-inch (DN80) size with a pressure rating of Class 300 LB (PN50). The valve is equipped with a rising stem handwheel for reliable manual operation and RF flanged ends for secure pipeline integration, making it ideal for cryogenic and cold service applications.

Detail Information

Product Name: ASTM A352 LCC Gate Valve, Rising Stem

Design Standard: API 600

Body Material: ASTM A352 LCC

Size: 3 Inch, DN80

Pressure: Class 300 LB, PN50

End Connection: RF Flanged

Operation: Handwheel

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Cast Steel Gate Valves are designed and manufactured to ensure VOC (volatile organic compounds) leakage of less than 100 ppm (parts per million). Extensive baseline laboratory testing, both static and cycle, has established the critical design parameters necessary for low-emission sealing in the stem packing and bonnet gasket areas. In-house testing procedures are routinely conducted to confirm that the standard product design and manufacturing processes consistently meet the maximum 100 ppm VOC leakage requirement prior to shipment.

Technical Specification

» Nominal Diameter: NPS 2-48 Inch (DN50–DN1200)

» Temperature Range: -29°C to 595°C

» Design Pressure: Class 150–2500 LB (PN10–PN420)

» Material: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C, CN3MN

» End Connections: Flanged (FF, RF, RTJ) to international standards

» Operation: Handwheel, Bevel Gear, Electric, Pneumatic

» Design and Manufacture Standards: ANSI B16.34, API 600, API 6D, API 603, BS 1414

» Face-to-Face (End-to-End): ANSI B16.10, API 6D

» Flanged Connection: 2–24 Inch to ANSI B16.5; 22 Inch, 26–36 Inch to MSS-SP-44 or API 605 upon request

» Test and Inspection: API 598, API 6D

» Butt-Welded End: ANSI B16.5

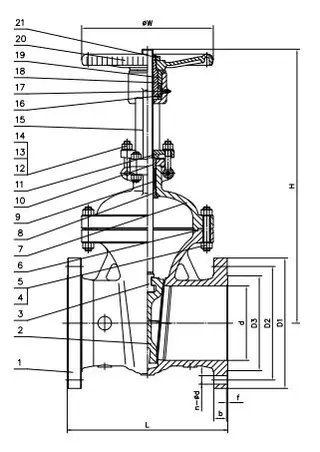

Structural Diagram

Product Features

» Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

» Grub screw: Secures yoke nut in the bonnet

» Grease nipple: Supplies lubricant to the mating parts

» OS&Y (Outside Stem and Yoke)

» Metal-sealed (API Trim #1, #5, #8, #10, etc.)

» Optional locking device or stem extension

» Optional direct mounting to ISO 5211

» Full port for minimal flow resistance