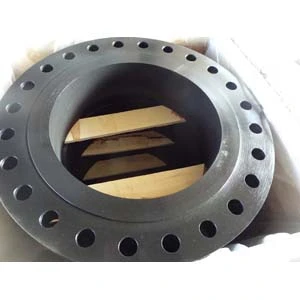

ASTM A350 LF3 Ball Valve, API 6D, 600 LB, Metal Seated, RF

Key Specifications / Features

Detail Information

Product Name: ASTM A350 LF3 Ball Valve, Metal Seated

Design Standard: API 6D

Body Material: ASTM A350 LF3

Size: Customized

Pressure: Class 600 LB, PN100

End Connection: RF

Operation: Gearbox

The ball and seat of the metal-seated ball valve feature a metal-to-metal sealing mode. Depending on the service conditions and user requirements, various advanced ball and seat hardening technologies can be employed, including HVOF coating, nickel-base alloy spray welding, high nickel alloy spray welding, nickel-base alloy tungsten carbide alloy spray welding, and cobalt-base hard alloy spray welding. The sealing face material can withstand heat resistance ranging from 540°C to 600°C, with a maximum value of up to 980°C. Additionally, the material exhibits excellent wear and impact resistance.

The seat is made of stainless steel with stellite alloy pile-up welding, while the ball is made of stainless steel and treated with three surface techniques: hard chrome plating, vacuum coating, and tungsten-titanium alloy as well as stellite alloy pile-up welding. These treatments ensure the ball meets the heat-resistance and wear-resistance requirements.

Our ball manufacturing process is innovative, achieving high-accuracy and super mirror surface processing. Another key feature of the metal-seated ball valve is the spring pre-pressing seat, which guarantees the absolute reliability of the seal and the stability of operating torque. This design ensures safety, sealing reliability, and operational flexibility, making the valve easy to operate while maintaining structural integrity.

Technical Specification

» Size Range: NPS 2-36 Inch (DN50–DN900)

» Design Pressure: Class 150–900 LB (PN10–PN160)

» Material: ASTM A105N, A350 LF2, A182 F304, F304L, F316, F316L, F51, etc.

» End Connections: RF, RTJ, BW

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other Specials

» Operation: Handle, worm gear, electric, pneumatic

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face to Face (End to End): ASME B16.10

» Flanged Connection: ASME B16.5, ASME B16.47

» Test and Inspection: API 598, API 6D

» Butt Welded End: ASME B16.25

» Fire Safety: API 607, API 6A

» Temperature Range: -29°C to 300°C

» Medium: Water, gas, oil, etc.

Features of Metal Seated Ball Valve

» Advanced Ball and Seat Hardening Technology

» Flexible Valve Opening and Closing

» Fireproof Structure Design

» Double Block and Bleed (Metal Seated Trunnion Ball Valve)

» Reliable Sealing Performance

» Blow-out Proof Stem

» Corrosion Resistance and Sulfide Stress Resistance

» Optional Locking Device or Stem Extension

» Optional Direct Mounting to ISO 5211

» Full Port or Reduced Bore