API 594 Dual Plate Check Valves, ASTM A216 WCB, 12 IN, CL300

Key Specifications / Features

The API 594 Dual Plate Check Valves Manufacturer offers a high-performance 12-inch, DN300 wafer check valve designed for efficient flow control and backflow prevention. This valve features a cast carbon steel body made from ASTM A216 WCB, providing excellent strength and durability. With a pressure rating of Class 300 LB and PN50, it is suitable for demanding industrial applications requiring high pressure and flow capacity. The raised face (RF) flanged connection ensures a secure and leak-tight seal, facilitating easy integration into existing piping systems.

Detail Information

Product Name: API 594 Dual Plate Check Valves

Type: Wafer Check Valve

Design Standard: API 594

Body Material: ASTM A216 WCB

Size: 12 Inch, DN300

Pressure: Class 300 LB, PN50

End Connection: RF Flanged

Temperature Range: -29°C to 595°C

Medium: Water, Gas, Oil, etc.

We are a specialized manufacturer of wafer check valves. These valves feature a central vertical pin shaft. When the valve is open, the resultant force of the fluid acts on the center of the sealing face of the disc. Meanwhile, the point of action of the counter spring support force is located at the center of the disc surface. This design ensures that the root of the disc opens first. This mechanism prevents the wear of the sealing surface that is common in traditional valves when they open, thereby enhancing the durability of the valve seal. The wafer check valve is a type of valve that automatically opens and closes based on the flow of the medium itself. It is primarily used to prevent the reverse flow of the medium.

Technical Specification

» Nominal Diameter: NPS 2–60 Inch (DN50–DN1500)

» Design Pressure: Class 150–2500 (PN10–PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» End Connections: wafer, Lug, Flanged.

» Design and Manufacture Standards: API 594, API 6D, JB/T 8937

» Face-to-Face (End-to-End): API 594, API 6D, JB/T 8937, DIN 3202

» Flanged Connection Standards: ANSI B16.5, DIN 2543–48, JB/T 9112–24

» Test and Inspection Standards: API 598, DIN 3230, JB/T 9092

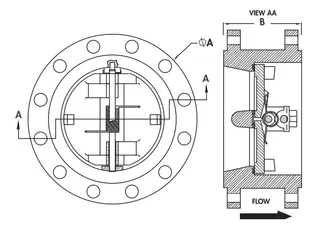

Structural Diagram

Product Features

» Light and Compact: Easy to install and handle due to its lightweight and compact design.

» Zero Leakage Sealing Design with Soft Seated: Ensures a perfect seal with zero leakage.

» Non-Slam Design: Prevents sudden closure and associated noise.

» Bubble Tight Closure: Achieves a tight seal that prevents any leakage, even at low pressures.

» Discs Open 85°: Ensures a low pressure drop for efficient fluid flow.