API 602 Cryogenic Globe Valve, A182 F316, 2 IN, CL 1500, BW

Key Specifications / Features

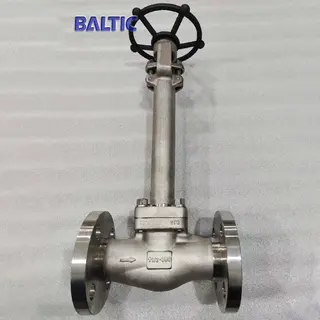

Presenting our API 602 Cryogenic Globe Valve Manufacturer, specializing in top-tier engineering. Crafted with ASTM A182 F316 forged stainless steel, our 2-inch valve meets Class 1500 LB and PN250 standards. Featuring a bolted bonnet, reduced bore, and BW ends, it ensures secure sealing and efficient fluid control. Trust in our valve for reliable performance in cryogenic applications.

Request a quote

Detail Information

API 602 Cryogenic Forged Globe Valve

Valve description: Bolted bonnet, Reduced bore, extended bonnet, solid wedge, renewable seat

Body material: ASTM A182 F316

Nominal diameter: 2 Inch (DN50)

Nominal class: Class 1500 LB (PN250)

End connection: BW

Metal seat: SS 316

Face to face: MFR, API 602

Mode of operation: Handwheel

Test and inspection: API 598

Typical cryogenic globe valve shown: Forged steel, outside screw and yoke (OS&Y), rising stem, non-rising handwheel. Full or conventional port. Bolted or welded bonnet joint. Integral backseat.

Design construction: API 602, ASME B16.34, BS 5352, BS 6364

Testing: API 598

Marking: MSS-SP 25 Outside Screw and Yoke (OS&Y) Self aligning two piece packing gland Spiral wound gasket Integral backseat

Face to face: ASME B16.10

Flanges: ASME B16.5 Welded body- bonnet joint also available

Socket Weld Ends: ASME B16.11

Screwed Ends (NPT): ASME B1.20.1

Butt Welding Ends: ASME B16.25

Ratings: Stainless Steel ASTM A182 F316

Valve description: Bolted bonnet, Reduced bore, extended bonnet, solid wedge, renewable seat

Body material: ASTM A182 F316

Nominal diameter: 2 Inch (DN50)

Nominal class: Class 1500 LB (PN250)

End connection: BW

Metal seat: SS 316

Face to face: MFR, API 602

Mode of operation: Handwheel

Test and inspection: API 598

Typical cryogenic globe valve shown: Forged steel, outside screw and yoke (OS&Y), rising stem, non-rising handwheel. Full or conventional port. Bolted or welded bonnet joint. Integral backseat.

Design construction: API 602, ASME B16.34, BS 5352, BS 6364

Testing: API 598

Marking: MSS-SP 25 Outside Screw and Yoke (OS&Y) Self aligning two piece packing gland Spiral wound gasket Integral backseat

Face to face: ASME B16.10

Flanges: ASME B16.5 Welded body- bonnet joint also available

Socket Weld Ends: ASME B16.11

Screwed Ends (NPT): ASME B1.20.1

Butt Welding Ends: ASME B16.25

Ratings: Stainless Steel ASTM A182 F316