The testing method of a thread

A. Using a thread gauge

How to use a thread gauge?

A screw thread is classified into an internal thread and an external thread.

We must clean oil and impurities on the thread gauge and the surface of the screw thread before thread inspection.

We can use a thread plug gauge to test an internal thread. The following shows that how to use a thread gauge.

How to use a thread gauge?

A screw thread is classified into an internal thread and an external thread.

We must clean oil and impurities on the thread gauge and the surface of the screw thread before thread inspection.

We can use a thread plug gauge to test an internal thread. The following shows that how to use a thread gauge.

- Align the end of the thread plug gauge with the thread, and use the thumb and index finger to turn the thread plug gauge or the part so as to make them rotated in a free state. Normally, the gauge of the thread plug gauge (the end) can be rotated at any position of the part. If the thread of the part passes through the length of the entire thread, the part will be qualified. Otherwise, it is a defective product. After the end of the gauge of the thread plug gauge align with the thread of the part, if the length of the screw thread is stopped within 2 thread pitches, it is qualified. The part cannot be forcefully passed, otherwise it is not qualified.

- When the workpiece is inspected, the thread plug gauge cannot be screwed tightly. Use your three fingers to screw it until it stops. The thread plug gauge cannot be pulled out forcefully, otherwise the product inspection will be affected. And the thread plug gauge will be damaged.

B. Using a thread ring gauge to test an external thread

- A thread ring gauge has two ring gauges which are a pair. When the workpiece is tested, one ring gauge should be screwed onto the workpiece smoothly and the other ring gauge should be screwed onto the workpiece with less than two screw pitches. Then, the workpiece is qualified.

- When the workpiece is inspected, the thread gauge cannot be screwed with force. Use your thumb and index finger to screw it until it stops.

C. Using a radius gauge

The testing method of a radius gauge

- When we measure the thread, the measuring surface of the radius gauge should be in close contact with the arc of the workpiece. If there is no gap between the measuring surface of the radius gauge and the arc of the workpiece. The figure on the radius gauge is the degree of the arc of the workpiece.

- Because it is visual inspection, the accuracy is not very high, which can only be used for observational measurement.

- Although there are limitations for a radius gauge, it is relatively easy to use it and we can avoid trouble of not being able to measure the thread.

D. Using a thread micrometer

A thread micrometer is used to measure the intermediate diameter of the workpiece. The detection method is the same as the outside micrometer. There are two ends which have the same shape as the thread of the workpiece. One is a cone, and the other is a groove. When the thread of the workpiece is tested, adjust the two ends of the thread micrometer so as to clamp the surface of the thread of the workpiece to the thread micrometer. The figure on the thread micrometer is the actual size of the medium diameter of the thread.

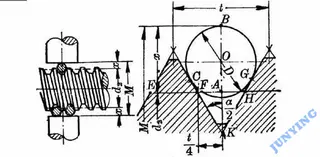

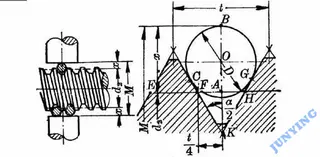

E. Using a measuring needle

The method of testing the medium diameter of the thread with a needle is called a three-needle (two-needle) measurement. When the thread is tested, a measuring needle of the same diameter D is placed in the groove of the thread, and use a thread micrometer to measure the size of M. These two measuring methods are mainly used to measure whether the diameter of the thread is correct or not, but the thread diameter itself has a tolerance, resulting in size differences. The accuracy is not very high.

The fast way to know whether a machining part has good quality or not.

A thread micrometer is used to measure the intermediate diameter of the workpiece. The detection method is the same as the outside micrometer. There are two ends which have the same shape as the thread of the workpiece. One is a cone, and the other is a groove. When the thread of the workpiece is tested, adjust the two ends of the thread micrometer so as to clamp the surface of the thread of the workpiece to the thread micrometer. The figure on the thread micrometer is the actual size of the medium diameter of the thread.

E. Using a measuring needle

The method of testing the medium diameter of the thread with a needle is called a three-needle (two-needle) measurement. When the thread is tested, a measuring needle of the same diameter D is placed in the groove of the thread, and use a thread micrometer to measure the size of M. These two measuring methods are mainly used to measure whether the diameter of the thread is correct or not, but the thread diameter itself has a tolerance, resulting in size differences. The accuracy is not very high.

The fast way to know whether a machining part has good quality or not.

- Check burr of the thread of the part

- Check if there is greasy dirt or crap in the thread

- Check whether the thread is clear and bright or not.

Send your message to this supplier

Related Articles from the Supplier

The testing method of a thread

- Jun 14, 2018

The Cause and Solution to Hardware Stamping Defect

- Feb 17, 2017

The Cause and Solution to Hardware Stamping Defect

- Apr 20, 2017

The Advantages of Aluminum Alloy Die Casting

- May 26, 2017

Related Articles from China Manufacturers

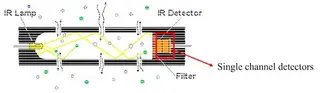

The Testing Principle of NDIR

- Jan 11, 2023

The Quality and Testing of Children's Swimsuits

- Oct 31, 2023

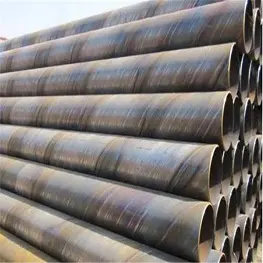

What Are The Testing Standards of Carbon Steel?

- Oct 26, 2020

Related Products Mentioned in the Article

Supplier Website

Source: http://www.junyingmetal.com/the-testing-method-of-a-thread.html