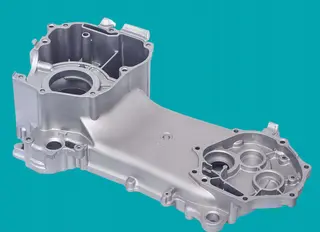

Causes and Repairing Methods of Aluminum Alloy Die Cast Scratches

With the continuous development of society, applications of aluminum alloy die casts also become very wide. Aluminum alloy die casts are often used for oil, industrial and mineral industries. In our daily life, this kind of die casting parts is mainly used in automotive field, thus so many people list die casting auto parts separately.

The main reasons for defects of aluminum alloy die castings are: surfaces of mold cavities are damaged; small inclination happen in the direction of demolding; balance occurs when the dies are ejected; the molds get loose.

We need to well control the casting molds when manufacturing aluminum die casts, and to make temperatures of the molds reach 200 degrees. We should use mold temperature controllers for aluminum die casts so as to accurately control the temperatures.

We need to repair mold surface damages timely and adjust inclinations of the molds in order to improve finishes of mold surfaces and make even force of knockout pins when we adjust them.

After a period of time, we ought to replace the release agents in time, and then reasonably adjust iron content and cooling time of aluminum alloy and timely modify flow gates.

The main reasons for defects of aluminum alloy die castings are: surfaces of mold cavities are damaged; small inclination happen in the direction of demolding; balance occurs when the dies are ejected; the molds get loose.

We need to well control the casting molds when manufacturing aluminum die casts, and to make temperatures of the molds reach 200 degrees. We should use mold temperature controllers for aluminum die casts so as to accurately control the temperatures.

We need to repair mold surface damages timely and adjust inclinations of the molds in order to improve finishes of mold surfaces and make even force of knockout pins when we adjust them.

After a period of time, we ought to replace the release agents in time, and then reasonably adjust iron content and cooling time of aluminum alloy and timely modify flow gates.

Send your message to this supplier

Related Articles from the Supplier

Causes of Die Casting Mold Failure

- May 10, 2017

Related Articles from China Manufacturers

Causes and Solutions of Ball Valve Internal Leakage

- Mar 27, 2019

Causes and Solutions of Water Hammer Issues

- Dec 01, 2023

Related Products Mentioned in the Article

Supplier Website

Source: https://www.china-die-casting.com/causes-and-repairing-methods-of-aluminum-alloy-die-cast-scratches.html