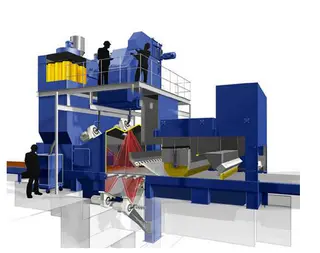

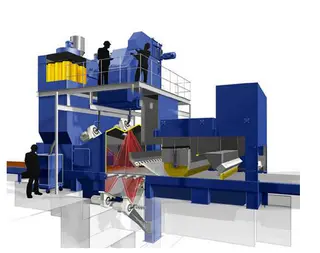

Automatic Metal Sheet Shot Blaster

Key Specifications / Features

Metal Sheet Shot Blaster Manufacturer JX Supplies Automatic Metal Sheet Shot Blasting Machine with Durable Parts, Suitable for Blasting Sheet Metal.

Request a quote

Detail Information

JX automatic sheet metal shot blasting machines are featured by high quality and durable parts, suitable for the blasting of profiles and plates. They are definitely effective for wear prevention.

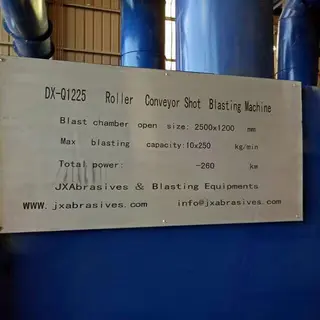

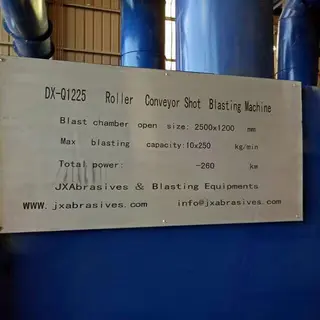

Technical data as below:

Total Power Total power: 263 kw

Total air volume: 38000 m³/h

| Name | Unit | Parameter | ||

| Blast chamber open size | mm | L2500×H1200 | ||

| Steel plate | width | mm | ≤2300 | |

| length | mm | 3000 - 12000 | ||

| thickness | mm | 6~40 | ||

| Steel structure | width | mm | ≤2000 | |

| height | mm | ≤1000 | ||

| length | mm | 3000~12000 | ||

| Material and strength | Q235, Q345, Q390 (Marine) A, B, C, D (steel), (Marine) AH32, AH36, DH32, DH36, EH36 | |||

| Working speed for conveyor | m/min | 0.5~4(frequency speed control) | ||

| Max. Loading for conveyor | kg/m | 1000 | ||

| Surface cleaning | A-B Sa2.5 grade GB8923-88(ISO8501) | |||

| Surface roughness | μm | Ra40~75(according to the size of steel shot ) | ||

Total power consumption |

Total power | kw | ≈263 | |

| Compressed air consumption | m³/min | 1 - 3 | ||

| Air pressure | MPa | 0.4 - 0.6 | ||

| Whole line | Max. height | mm | Up ground ≤7000(belowed ground≤2190) | |

| Total length | mm | 34500 | ||

| The request for foundation | Waterproof | |||

Technical data as below:

| 1. Blasting chamber Blast Chamber Open Size: 2500mm - 1200mm. 2. Roller conveying system Working speed: 0.5 - 4 m/min Power: 4x2 kw 3. Blasting nozzles Model: Q034H Shot blasting volume: 250 - 10 kg/min Power: 15 - 10 kw Quantity: Set 10 4. Portrait & horizontal Screw Conveyor Portrait Delivery capacity: 150 t/h Power: 7.5 kw Horizontal delivery capacity: 150 t/h Power: 5.5 kw 5. Bucket Elevator Lifting capacity: 150 t/h Power: 11 kw |

6. Separator Separating capacity: 150 t/h Air speed in separating area: 4 - 5 m/s Power: 5.5 kw 7. Dust Collector system Pulse cartridge Dust Collector Quantity: set 2 8. Reverse Blower Air volume: 9000 X 2 m³/h Power: 18.5+ 11 kw 9. Lifting system for cleaning Brush Lifting distance: 0 - 1200 mm Power: 2.2 x2 kw 10.Cleaning brush Diameter of brush: 600 mm Power: 3 kw |

Total air volume: 38000 m³/h