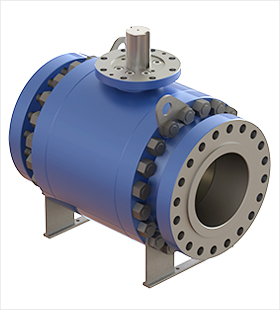

Metal Seated Trunnion Mounted Ball Valve

Key Specifications / Features

Metal Seated Trunnion Mounted Ball Valve Manufacturer in China: Metal Seated Trunnion Mounted Ball Valve, ASTM A105N or ASTM A182 F316, 2 - 24 Inch, Class 150 - 2500 LB.

Request a quote

Detail Information

Body material: ASTM A105N or ASTM A182 F316

Severity Service

Normal soft-seated valve can not be used for abrasive service or for operation under high temperatures that prohibits the use of a resilient material. VIZA metal-to-metal seated floating ball valve (series TM, range 2 Inch - 24 Inch, Class 150 - 2500 LB) is designed for this type of severity service has seating action provided by the metal to metal contacting seating action is provided between ball and seat ring.

General Design

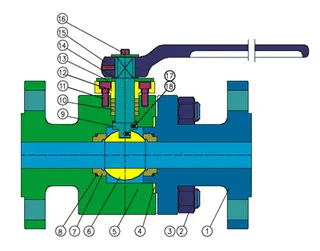

Blow-out proof stem, anti-static device, double block & bleed, self relieving seats, mechanical stops for ball seat alignment are designed as standard requirements; while for fire safe and sealant injection system will be supplied when service request.

Superior Sealing

High precision machining and seat to ball rubbing result in superior ball and seat interfacing for reliable sealing conforming to ANSI/FCI 70-2 class V.

Reliable Operations

Spring-loaded seats maintain close contacting with the ball ensuring tight sealing even at low pressures. This also results in stable operating torques at high differential pressures over a wide range of temperatures or/and high frequency.

Material Selection

Various materials can be chosen from for the service up to 500°C. For service temperature above 300°C, the extension bonnet is required.

Applications

Hard faced ball and seats (TCC as standard, other special coatings are available on request) allow the valve to be used in more severe services such as slurries, pulp stock, mining and other abrasive media in long life.

Severity Service

Normal soft-seated valve can not be used for abrasive service or for operation under high temperatures that prohibits the use of a resilient material. VIZA metal-to-metal seated floating ball valve (series TM, range 2 Inch - 24 Inch, Class 150 - 2500 LB) is designed for this type of severity service has seating action provided by the metal to metal contacting seating action is provided between ball and seat ring.

General Design

Blow-out proof stem, anti-static device, double block & bleed, self relieving seats, mechanical stops for ball seat alignment are designed as standard requirements; while for fire safe and sealant injection system will be supplied when service request.

Superior Sealing

High precision machining and seat to ball rubbing result in superior ball and seat interfacing for reliable sealing conforming to ANSI/FCI 70-2 class V.

Reliable Operations

Spring-loaded seats maintain close contacting with the ball ensuring tight sealing even at low pressures. This also results in stable operating torques at high differential pressures over a wide range of temperatures or/and high frequency.

Material Selection

Various materials can be chosen from for the service up to 500°C. For service temperature above 300°C, the extension bonnet is required.

Applications

Hard faced ball and seats (TCC as standard, other special coatings are available on request) allow the valve to be used in more severe services such as slurries, pulp stock, mining and other abrasive media in long life.