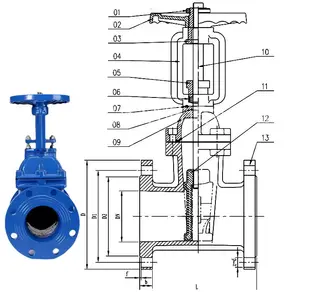

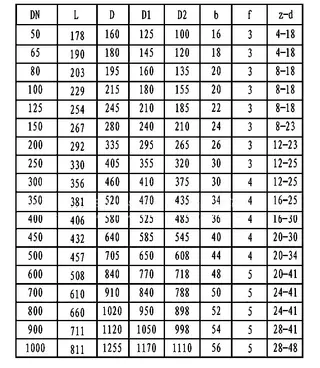

Rising Stem Gate Valves, DIN 3352, Ductile Iron, DN50-DN300

Key Specifications / Features

The Rising Stem Gate Valves Plant in China specializes in producing high-quality gate valves with DN50 to DN300 (2 to 12 inches) sizes, designed to meet DIN 3352 standards. These valves feature ductile iron bodies and rubber seals, ensuring durability and excellent sealing performance. They are available in PN10/PN16 pressure ratings and Class 150 LB, with flanged ends for easy installation and compatibility with various piping systems.

Detail Information

Product Name: Ductile Iron Rising Stem Gate Valve, Soft Sealed

Design Standard: DIN 3352

Model Number: Z41X

Body Material: Ductile Iron

Sealing Material: Rubber

Nominal Diameter: DN50-DN300, 2-12 Inch

Pressure Range: 1.0-1.6 MPa, PN10/PN16, Class 150 LB

Connection Type: Flange

Certificates: TA-Luft, ISO 15848-1, API 622, ect

Flange Standard: ASME B16.5

Face to Face Standard: ASME B16.10

Testing Standard: API 598

Operating Temperature: ≤ 80°C

Common Medium: Water, Oil, Gas, etc.

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.