EN 1.4408 Gate Valve, DIN 3352 F4, DN100, PN10, Rising Stem

Key Specifications / Features

The EN 1.4408 Gate Valve Manufacturer offers a high-quality rising stem gate valve designed for reliable performance in various industrial applications. This valve features a stainless steel body made from EN 1.4408 material, providing excellent corrosion resistance and durability. It conforms to the DIN 3352 F4 standard. With a nominal diameter of DN100 (4 inches) and a pressure rating of PN10 (Class 150 LB). The valve is equipped with RF (Raised Face) flanged ends for secure and leak-free connections. Operated by a handwheel, it allows for easy manual control.

Detail Information

Product Name: EN 1.4408 Gate Valve, Rising Stem

Design Standard: DIN 3352 F4

Body Material: EN 1.4408

Size: DN100, 4 Inch

Pressure: PN10, Class 150 LB

End Connection: RF Flanged

Operation: Handwheel

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Wedge Gate Valves are meticulously designed and manufactured to achieve ultra-low leakage rates, specifically less than 100 ppm (parts per million) of volatile organic compounds (VOCs). This stringent emission control is a result of extensive baseline laboratory testing, which includes both static and cycle testing. These tests have been instrumental in establishing critical design parameters that ensure low-emission sealing in key areas such as the stem packing seal and the bonnet gasket sealing area. To maintain the highest standards of quality and performance, an in-house testing procedure has been developed. This procedure is periodically executed to verify that the standard product design and manufacturing criteria consistently result in the Wedge Gate Valve meeting the maximum allowable leakage rate of 100 ppm VOCs prior to shipment. This rigorous approach guarantees that each valve is reliable, efficient, and environmentally friendly, making it suitable for a wide range of demanding applications.

Technical Specification

» Nominal Diameter: DN50-DN1000, 2-40 Inch

» Temperature Range: -29°C to 595°C

» Design Pressure: PN6 to PN16, Class 125, 150 LB

» Body/Bonnet/Wedge Materials:

Cast Steel (EN 1.0619)

Stainless Steel (EN 1.4308, EN 1.4408)

Alloy Steel (EN 1.7335 / ASTM A217 WC6)

» Stem: X20Cr13 or EN 1.4021; Stainless Steel (EN 1.4308, EN 1.4408)

» Seat Options: 13Cr, 18Cr, Stellite

» End Connections: RF Flange, Groove Flange, Butt Weld (BW)

» Operation Modes: Handwheel, Bevel Gear, Electric, Pneumatic

» Structure: BB-BG-OS&Y (Bolted Bonnet, Bolted Gland, Outside Stem & Yoke)

» Design Standard: DIN 3352

» Face-to-Face Dimensions: EN 558-1 Series 14 (DIN 3202 F4 series)

» Flange Standards: DIN 2543–2547, EN 1092-1, GOST 12815/12819

» Butt Weld Ends: EN 12627

» Testing & Inspection: DIN 3230

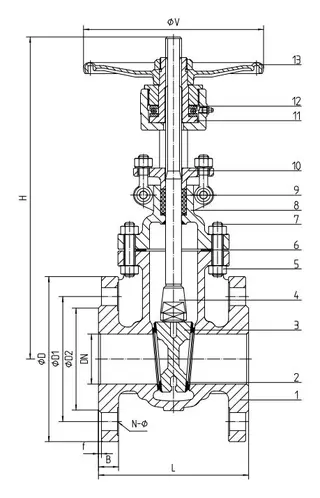

Structural Diagram

Product Features

» Anti-friction Ball Thrust Bearing: This feature reduces friction between mating parts, ensuring smooth operation and extending the service life of the valve.

» Grub Screw: Secures the yoke nut in the bonnet, providing a stable and reliable connection.

» Grease Nipple: Allows for the supply of lubricant to the mating parts, reducing wear and tear and ensuring consistent performance.

» OS&Y (Outside Stem and Yoke): This design allows for easy inspection and maintenance without the need to remove the valve from the pipeline.

» Metal-sealed Trim Options: Available in various trim types such as #1, #5, #8, #10, and more, ensuring compatibility with different media and operating conditions.

» Optional Locking Device or Stem Extension: Provides additional security and ease of operation, tailored to specific application needs.

» Optional Direct Mounting to ISO 5211: Allows for direct mounting to actuators conforming to the ISO 5211 standard, enhancing versatility and compatibility.

» Full Port: Ensures unrestricted flow through the valve, minimizing pressure drop and maximizing efficiency.