Y Strainer with Pressure Gauge, A351 CF8, 4 Inch, 300 LB, RF

Key Specifications / Features

This Cast Steel Y Strainer is built for efficient filtration and system protection, featuring a pressure gauge for real-time monitoring. Constructed from corrosion-resistant ASTM A351 CF8 stainless steel and designed to ANSI B16.34 standards, it offers durability and reliability in demanding applications. With a 4-inch (DN100) size, Class 300 LB (PN50) pressure rating, and RF flanged ends, this Y strainer is ideal for removing debris in pipelines across chemical, water treatment, and industrial systems.

Detail Information

Product Name: Cast Steel Y Strainer with Pressure Gauge

Type: Y Type Strainer

Design Standard: ANSI B16.34

Body Material: ASTM A351 CF8

Size: 4 Inch, DN100

Pressure: Class 300 LB, PN50

End Connection: RF Flanged

Medium: Steam (High-temperature), Gas, Oil, etc.

Temperature Range: -29°C to 425°C

As a key component in purification system engineering, Y-type strainers serve as high-efficiency filtration devices widely used in both domestic and industrial wastewater treatment. With their superior design and versatile application, these strainers have become highly favored in various industries. They play a critical role in filtering large volumes of wastewater, enabling the effective reuse of valuable water resources and significantly reducing water waste.

Y-type strainers stand out due to their operational advantages, including full automation, maintenance-free performance, large filtration area, high filtration efficiency, extended service life, stainless steel construction, customizable filtration precision, and a wide range of specifications. Compared with other filtration equipment, Y-type strainers are among the most effective in engineering applications. The treated water not only complies with national discharge standards but also becomes suitable for reuse, supporting sustainability and cost-efficiency.

Technical Specification

» Normal Size Range: 1/2-24 Inch (DN15-DN600)

» Normal Pressure Rating: PN16-PN420, Class 150-2500 LB

» Material: ASTM A216 WCB, A351 CF8, CF8M, CF3, CF3M, A352 LF2, A217 WC6, WC9

» Filtering Accuracy:

18-30 mesh for water filter

10-100 mesh for air filter

100-480 mesh for oil filter

» Temperature Range: -29°C to +425°C

» End Connections: RF, RTJ, BW

Standards Compliance

» Design and Manufacture: ANSI B16.34, API 600, API 6D

» Face to Face (End to End): ANSI B16.10, API 6D

» Flanged Connection: 2-24 Inch to ANSI B16.5

» Test and Inspection: API 598, API 6D

» Butt Welded End: ANSI B16.5

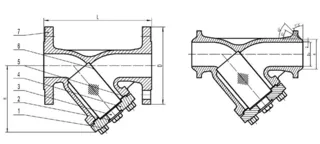

Structural Diagram

Material for Main Parts

|

No |

Name of Parts |

Carbon steel |

Stainless steel |

Stainless steel |

|

1 |

Bolt |

A193 B7 |

A193 B8 |

A193 B8M |

|

2 |

Gasket |

Copper Alloy |

Copper Alloy |

Copper Alloy |

|

3 |

Drain plug |

A105 |

SS 304 |

SS 316 |

|

4 |

Bonnet |

A216 WCB |

A351 CF8 |

A351 CF8M |

|

5 |

Gasket |

Graphite + SS |

Graphite + SS |

Graphite + SS |

|

6 |

Screen |

SS 304 |

SS 304 |

SS 316 |

|

7 |

Body |

A216 WCB |

A351 CF8 |

A351 CF8M |

Send your message to this supplier

FAQs

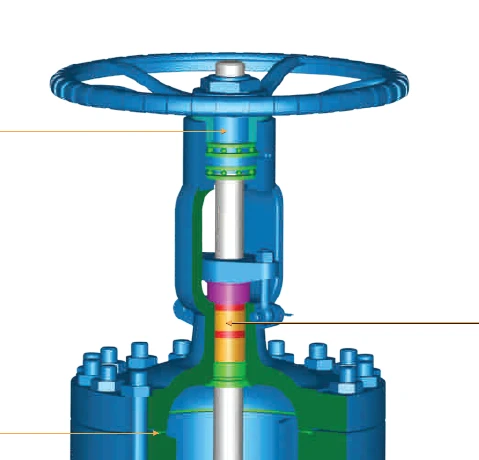

OS&Y stands for Outside Screw and Yoke. This design places the threaded stem outside the valve body, with the yoke supporting the stem. It allows users to visually verify whether the valve is open or closed by observing the stem’s position.

OS&Y gate valves are commonly used in fire protection systems, including sprinklers, hydrants, and standpipes, due to their reliability and clear open/close indication.