SS 904L Wedge Gate Valve, Stainless Steel, 2 Inch, CL300, RF

Key Specifications / Features

Detail Information

Product Name: SS 904L Wedge Gate Valve

Type: Wedge Gate Valve

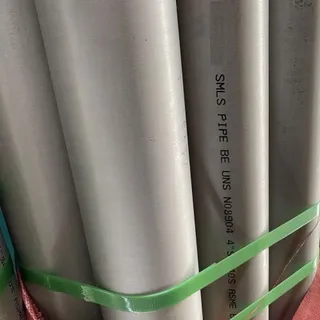

Body Material: Stainless Steel SS 904L

Size: 2 Inch, DN50 (50 mm)

Pressure: Class 300 LB, PN50

End Connection: RF Flanged

Operation: Handwheel

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Cast Steel Gate Valves are designed and manufactured to limit volatile organic compound (VOC) emissions to less than 100 ppm (parts per million). Extensive baseline laboratory testing, including both static and cyclic tests, has been conducted to identify and validate the critical design parameters required to achieve low-emission sealing performance. These parameters focus primarily on the stem packing seal area and the bonnet gasket sealing area. In addition, dedicated in-house testing procedures have been developed and are performed periodically to verify that standard product design and manufacturing practices consistently ensure our Cast Steel Gate Valves meet a maximum VOC leakage level of 100 ppm prior to shipment.

Technical Specification

» Nominal Diameter: NPS 1/2-48 Inch (DN15-DN1200)

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M, CF8C, CN3MN, CK3MCUN, CN7M, A890 4A (CD3MN), 5A (CE3MN), 6A (CD3MWCuN), B148 C95800, C95500

» End Connections: Flanged (FF, RF, RTJ) to international standards

» Operation: Hand wheel, bevel gear, electric, pneumatic

» Design and Manufacture: ANSI B16.34, API 600, API 6D, API 603, BS 1414

» Face to Face (End to End): ANSI B16.10, API 6D

» Flanged Connection: 2-24 Inch to ANSI B16.5, 22 Inch, 26-36 Inch to MSS-SP-44 or to API 605 on request

» Test and Inspection: API 598, API 6D

» Butt Welded End: ANSI B16.25

Product Features

» Anti-friction ball thrust bearing: Reduces friction between mating components, ensuring smooth and reliable operation

» Grub screw: Securely locks the yoke nut within the bonnet

» Grease nipple: Allows easy lubrication of mating components to reduce wear

» OS&Y (Outside Stem and Yoke) design for clear visual indication of valve position

» Metal-seated trim, API Trim Nos. 1, 5, 8, 10, and others available

» Optional locking device or stem extension for enhanced safety and accessibility

» Optional direct mounting in accordance with ISO 5211

» Full-port design for maximum flow capacity and minimal pressure drop