Plastic Diaphragm Pump, PP, PVDF, PTFE, DN10-DN125, Threaded

Key Specifications / Features

Detail Information

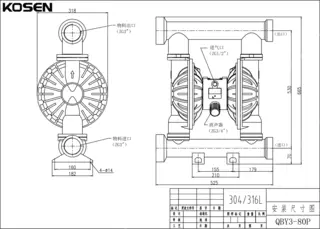

Product Name: Plastic Diaphragm Pump

Port Sizes: 10-125 mm, DN10-DN125

Temperature: -20°C to 150°C

Pump Material: Polypropylene (PP, PVDF, PTFE)

Diaphragm Material: VITON, PTFE, EPDM, NBR

Ball Material: PTFE, Stainless Steel, VITON, Ceramic

Seat: PTFE, Stainless Steel, VITON

Maximum Particle Diameter: 6 mm

Connection: Threaded End

Medium: Various Chemicals: Acids, Alkalis, Solvents, etc.

The QBY3 Pneumatic Diaphragm Pump is the third generation of diaphragm pumps developed by our company, offering reliable performance and an extended service life. It operates with minimal noise, vibration, and risk of damage. The pump is designed with fine craftsmanship and six key advantages, making it suitable for pumping liquid flows as well as transporting easily flowing media. It serves as a versatile alternative to other types of pumps such as submersible pumps, shielding pumps, and mud and trash pumps.

Diaphragm Pump Advantages

» High Suction Lift & Pressure: No irrigation water required, capable of suction lifts up to 5 meters and head heights up to 70 meters, with an outlet pressure of ≥ 7 bar.

» Versatile Performance: Suitable for pumping mud, impurities, and particles up to 10 mm in diameter with minimal wear on the pump.

» Stepless Adjustment: Head and flow can be smoothly adjusted via the valve opening degree, with pressure adjustment ranging between 1-7 bar.

» Leak-Free Operation: No moving parts or shaft seals, ensuring that the working medium is completely separated from the transmission medium, preventing leakage. This makes it ideal for pumping toxic, volatile, or corrosive substances safely without environmental or safety hazards.

» Electricity-Free: Operates without electricity, making it safe and reliable for use in flammable and explosive environments.

» Immersion Capability: The pump can be fully immersed in the medium during operation.

» Easy Operation & Self-Protective Features: Simple to operate with a gas valve to start and stop. In the event of an accident or sudden stop, the pump will not be damaged by the absence of medium. If the pump overloads, it will automatically shut down and restart once normal load conditions are restored.

» Simple Structure & Low Wear: The simple design and minimal moving parts reduce wear and tear. Unlike other pumps that rely on rotors, pistons, or gears, the QBY3 diaphragm pump avoids gradual performance decline from wear.

» Viscosity Handling: Capable of handling liquids with viscosities of up to 10,000 cps.

» No Lubrication Required: The pump does not require lubricating oil, and it operates effectively even when idling without damage.

» Flange Pressure Ratings: Plastic flange pressure: PN6, 0.6 MPa (10 bar); Metal flange pressure: PN10, 1.0 MPa (10 bar).