Inverted Type Plug Valve, API 6D, A216 WCB, 12 Inch, 600 LB

Key Specifications / Features

Detail Information

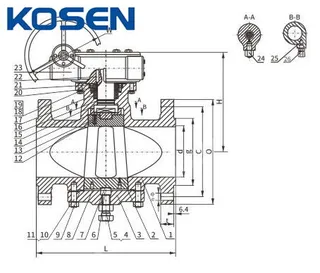

Product Name: Inverted Type Plug Valve

Design Standard: API 6D, API 599

Body Material: ASTM A216 WCB

Size: 12 Inch, DN300

Pressure: Class 600 LB, PN100

End Connection: RF

Operation: Worm Gear

We manufacture high-quality Lubricated Plug Valves, offering competitive pricing and custom design options based on ANSI standards. These valves are widely used in industries such as petroleum, chemicals, pharmaceuticals, fertilizers, and power. Our Flange End Lubricated Plug Valves can be tailored to meet specific customer requirements. Also known as Pressure Balance Lubricated Plug Valves, they are designed to provide reliable sealing and smooth operation in various applications.

Technical Specifications

» Nominal Diameter: NPS 1/2-16 Inch (DN15-DN400)

» Design Pressure: Class 150-1500 LB (PN20-PN260)

» Material: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M, CF8C, CN3MN, CN7M, A890 4A (CD3MN), 5A (CE3MN), 6A (CD3MWCuN), B148 C95800, C95500

» Design Standard: API 6D, API 599

» Face to Face: ASME B16.10

» Test Standard: API 598, ISO 5208

» Connection End: RF, RTJ, BW

» Design Temperature: -46°C to +300°C

» Applicable Medium: Water, steam, oil, gas, etc.

» Operation: Lever, worm gear, electric, pneumatic

» Applications: Petrochemical, chemical, natural gas, LPG, HVAC, food, and pharmaceuticals

» Key Functions

Function 1: Optional bore patterns: Venturi, Regular, Short, Standard

Function 2: Metal-to-metal seated design

Function 3: Injection grease sealed design (for stem and seats)

Function 4: Fire-safe design

Product Characteristics

The inverted pressure balance plug valve design ensures smooth and balanced operation under pressure from different directions. It features special sealing structures that effectively prevent fluid leakage when the valve is closed, ensuring reliable and secure performance in various applications.