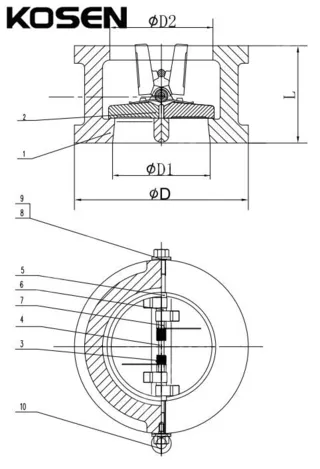

Dual Plate Wafer Check Valve, API 594, CF8M, 4 IN, CL900

Key Specifications / Features

Detail Information

Product Name: Dual Plate Wafer Check Valve

Design Standard: API 594

Body Material: ASTM A351 CF8M

Size: 4 Inch, DN100

Pressure: Class 900 LB, PN150

We are a specialized manufacturer of wafer check valves. These valves feature a unique design with a central vertical pin shaft. When the valve opens, the resultant fluid force acts on the center of the sealing face of the disc, while the counter spring support force is applied at the center of the disc surface. This design ensures that the root of the disc opens first, preventing wear on the sealing surface, a common issue with traditional valves. As a result, the valve seal's longevity is significantly improved. Wafer check valves are self-acting valves that open and close automatically based on the flow of the medium, and they are primarily used to prevent reverse flow.

Technical Specifications

» Nominal Diameter: NPS 2–60 Inch (DN50–DN1500)

» Design Pressure: Class 150–2500 (PN10–PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» End Connections: Wafer, Lug, Clamp, Flanged

» Design and Manufacture Standards: API 594, API 6D, JB/T 8937

» Face-to-Face (End-to-End): API 594, API 6D, JB/T 8937, DIN 3202

» Flanged Connection Standards: ANSI B16.5, DIN 2543–48, JB/T 9112–24

» Butt Welded End Standards: ANSI B16.25

» Test and Inspection Standards: API 598, DIN 3230, JB/T 9092

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

Product Features

» Light and Compact: Easy to install and saves space.

» Leak-Free Seal: Soft seat design prevents leaks for better reliability.

» Non-Slam: Smooth operation with no sudden closures.

» Tight Shutoff: Ensuring no leakage, even under pressure.

» 85° Disc Opening: Reducing pressure drop and improves flow.