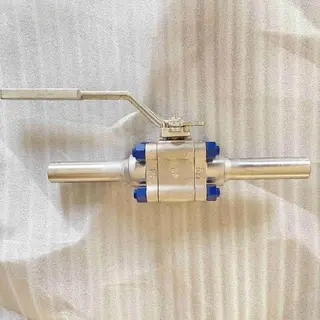

Bolted Bonnet Ball Valve, ASTM A216 WCB, 2 IN, 3000 PSI, NPT

Key Specifications / Features

Detail Information

Product Name: Bolted Bonnet Ball Valve

Body Material: ASTM A216 WCB

Size: 2 Inch, DN50

Pressure: 3000 PSI

End Connection: NPT

Operation: Lever

Application: Oilfield

NACE: NACE MR0175

This ball valve is specifically designed for oil field applications, featuring a robust construction that ensures reliable performance under high pressure. The valve includes a body and a valve tube, with valve tubes located on both the left and right sides. Its design incorporates a second slide rail within the inner cavity, while the valve rod is equipped with a stable block and a handwheel for efficient manual operation. A limit device within the valve rod enhances operational precision and safety.

Technical Specifications

» Design Pressure: 2500 PSI, 3000 PSI, and 5000 PSI

» Materials:

ASTM A216 WCB for 2500 and 3000 PSI body

ASTM A487 4C for 5000 PSI body

» Size Range:

NPS 2 Inch RP, 2 Inch FP

NPS 3 Inch FP

» Temperature Range: -20°C to 120°C.

» End Connections:

ASME B1.20.1 (NPT)

API 5B LP

» Medium: Suitable for water, oil, and gas applications.

Structural Features

» Back-Seated Stem: Blowout-proof and fire-safe design for enhanced durability and safety.

» External Stem Lubrication: Ensures smooth operation and reduces wear.

» Vented Weather Seal: Protects the valve from external environmental factors.

» Corrosion Resistance: Stainless steel trim provides maximum protection against corrosion.

» Port Configurations: Available in full port (FP) and reduced port (RP) options.

» Pressure Equalization: The ball features a pressure equalization hole to prevent trapped pressure in the body cavity.

» Locking Mechanism: Standard locking handle with a double-locking feature for improved safety and security, particularly for tank valve applications.

» Compliance: Meets NACE MR0175 standards for corrosion resistance in sour gas environments.

» Inspection and Testing: Certified to API 598 standards.

Materials of Main Parts

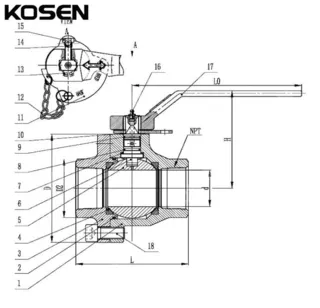

|

No |

Part |

Matarial |

|

|

1 |

Body |

ASTM A216 WCB |

ASTM A487 4C |

|

2 |

Body Seal |

VITON |

|

|

3 |

Bonnet |

ASTM A216 WCB |

ASTM A487 4C |

|

4 |

Seats |

DELRIN |

|

|

5 |

Ball |

ASTM A276 420 |

|

|

6 |

Stem |

ASTM A276 420 |

|

|

7 |

Thrust Bearing |

PTFE |

|

|

8 |

Stem Seal |

VITON |

|

|

9 |

Stem Seal |

VITON |

|

|

10 |

Stem Bearing |

PTFE |

|

|

11 |

Stop Plate |

CS+Ni |

|

|

12 |

Pin with chain |

Stainless Steel |

|

|

13 |

Retainer Ring |

Spring Steel |

|

|

14 |

Stop Pin |

Spring Steel |

|

|

15 |

Screw |

Carbon Steel |

|

|

16 |

Grease Zerk |

Carbon Steel |

|

|

17 |

Handle |

Ductile Iron |

|

|

18 |

Cap Screw |

ASTM A193 B7M |

|

Dimensions of main (Inch)

|

Size |

Port |

L |

D |

D2 |

d |

H |

Lo |

Weight (Lbs) |

Torque (in.Lb) |

|

2 Inch |

RP |

5.5 |

4.92 |

3 |

1.5 |

4.94 |

10 |

13.12 |

1750 |

|

2 Inch |

RP |

5.5 |

4.92 |

3 |

1.5 |

4.94 |

10 |

13.12 |

2700 |

|

2 Inch |

FP |

5.75 |

5.91 |

3.13 |

2 |

5.32 |

10 |

19.6 |

2350 |

|

2 Inch |

FP |

5.75 |

5.91 |

3.13 |

2 |

5.32 |

10 |

19.6 |

3850 |

|

2 Inch |

FP |

8.13 |

7.87 |

4.53 |

3 |

7.31 |

20 |

48.94 |

4100 |

|

2 Inch |

FP |

8.13 |

7.87 |

4.53 |

3 |

7.31 |

31.5 |

49.93 |

7080 |