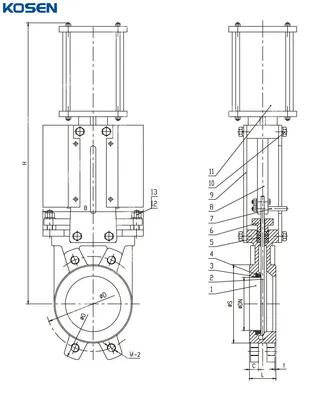

ASTM A351 CF8 Knife Gate Valve, DN200, PN10, 8 IN, Pneumatic

Key Specifications / Features

The ASTM A351 CF8 Knife Gate Valve, with a stainless steel body, is designed for robust performance in harsh environments. It features a 200mm (DN200) size, supporting PN10 and Class 150 LB pressure ratings. Equipped with wafer ends for efficient installation, the valve also comes with a pneumatic actuator and limit switches for automated operation and precise control.

Detail Information

Product Name: Pneumatic Knife Gate Valve with Limit Switches

Body Material: ASTM A351 CF8

Size: DN200, 8 Inch

Pressure: PN10, Class 150 LB

End Connection: Wafer

Operation: Pneumatic Actuator

The knife gate valve is a unidirectional wafer valve specifically designed for on-off operations in industrial pipelines. Its unique structure effectively prevents clogging during shutdown, even when handling flows containing particles. The beveled knife gate design enhances shear stress, facilitating smooth flow penetration.

Technical Specification

» Structure: Bonneted Knife Gate Valve

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: PN10, PN16, Class 150 LB

» Max Working Pressure:

DN50 to DN250: 10 bar

DN300 to DN450: 7 bar

DN500 to DN600: 4 bar

» Body Material: Ductile Iron, Carbon Steel, Stainless Steel, Special Alloys, etc.

» Disc Material: Stainless Steel Chrome Plated, Special Alloys, etc.

» Seat Material: Stainless Steel + STL, EPDM (120°C), Viton (200°C), PTFE (200°C), NBR (80°C)

» Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN 1092-1

» Face to Face: MSS SP-81

» Applications: Pulp & Paper, Water Treatment, Beverage & Food, Fine Chemicals, Power Plants, Steel Industry, etc.

» Temperature Range: -29°C to +538°C

Product Features

» Cast-in Guide Claws: Guide claws at the port bottom securely hold the gate, replacing traditional grooves. This design prevents clogging during shutoff and ensures a tight seal. The claws push the gate towards the seat for a secure seal when closed.

» Integral Body Design: The one-piece body construction simplifies assembly and guarantees zero shell leakage, enhancing reliability.

» Full Port Design: The full port design minimizes pressure drop and maximizes flow capacity, ensuring efficient fluid transfer.

» PTFE Resilient Seals: PTFE seals on the gate eliminate metal-to-metal contact with the body, reducing wear and improving durability.

» Super Thin Body: The ultra-thin body and compact construction make the valve easy to install in tight spaces.

» Beveled Knife Edge: The beveled knife edge provides strong cutting stress and ensures tight sealing, even with abrasive or particulate-laden flows.

» Adjustable Gate Thickness: The gate thickness can be increased to meet higher pressure requirements, offering versatility.

» Replaceable Side-Entry Seat: The side-entry seat is easily replaceable, reducing maintenance costs and downtime.

» L-Shaped Seat Retainer: The L-shaped seat retainer locks the seat securely into the valve body and protects it from direct flow flushing, extending its life.

» Stem: Cover An optional stem cover enhances the durability and longevity of the stem.

» Low-Torque Operation: Two thrust bearings minimize the torque required for operation, making the valve easier to use.

» Grease Nipple: An optional grease nipple facilitates easy bearing lubrication, ensuring smooth operation and reducing maintenance.