Through Conduit Knife Gate Valve, ASTM A351 CF8, DN100, PN10

Key Specifications / Features

Detail Information

Product Name: Through Conduit Knife Gate Valve, Split-body, Full Port

Body Material: ASTM A351 CF8

Seat Material: PTFE

Size: 4 Inch, DN100

Pressure: Class 150 LB, PN10

End Connection: Wafer

Operation: Manual

The Through Conduit Knife Gate Valve is a bi-directional wafer knife gate valve designed primarily for highly concentrated flow media. Featuring a through-going O-port plate, this valve offers reliable and safe shut-off performance without the risk of clogging. Its double-seat design enables it to handle flow in both directions, ensuring versatility in a wide range of applications.

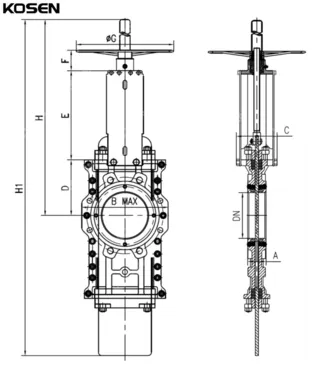

Technical Specifications

» Structure: Through Conduit Knife Gate Valve

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: PN10, PN16, Class 150 LB

» Temperature Range: -29°C to 150°C

» Max Working Pressure:

DN50-DN250: 10 bar

DN300-DN450: 7 bar

DN500-DN600: 4 bar

» Body Material: ASTM A216 WCB, A351 CF8, CF8M, Special Alloys, etc.

» Seat Material: PTFE (up to 150°C)

» Flange Standard:

GB/T 9113.1

JB/T 79.1

HG 20592

ASME B16.5

EN 1092-1

» Face to Face: MSS SP-81

» Operation: Manual, Bevel Gear, Pneumatic, Electric, Hydraulic

» Ends Connections: Wafer Type

Product Features

» Split-Body Design: The machined inner body prevents media adhesion within the valve cavity, ensuring smooth operation.

» Full Port Design: Minimizes pressure drop and maximizes flow capacity for efficient operation.

» Double Packing: Packing at both the top and bottom eliminates leakage to the surrounding environment, ensuring a tight seal.

» Through Gate with O-Port: The gate cuts through the media with an O-port disc when closing, and the portion is returned when opening. Gate thickness can be increased for higher pressure applications.

» Polished Gate Surface: Both sides of the gate are polished to provide a tight seal and minimize jamming.

» Hard Chrome Coating: The gate is coated for enhanced metal sealing and durability.

» Replaceable Side-Entry Seat: Reduces maintenance costs by allowing easy seat replacement.

» L-Shape Seat Retainer: Locks the seat into the valve body and covers the seat side to prevent direct flow flushing.

» Bi-Directional Flow: With seats on both sides, the valve can handle flow in both directions equally.

» Stem Cover: Available to protect the stem and extend its service life.

» Low Torque Operation: Two thrust bearings are used to minimize torque for easier operation.

» Grease Nipple: For easy lubrication of bearings, ensuring smooth and long-lasting valve performance.