ASTM A216 WCB Y Globe Valve, BS 1873, 3 IN, CL1500, PSB, BW

Key Specifications / Features

Detail Information

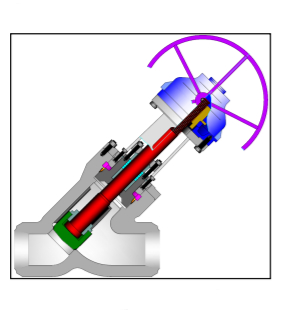

Product Name: Y Pattern Pressure Sealed Globe Valve

Design Standard: BS 1873, ASME B16.34

Body Material: ASTM A216 WCB

Size: 3 Inch, DN80

Pressure: Class 1500 LB, PN250

End Connection: BW End

Operation: Handwheel

The pressure seal globe valves are engineered in compliance with BS1873 and ASME B16.34 standards, making them ideal for high-temperature and high-pressure applications, particularly in fossil fuel power plants. Compared to bolted bonnet joint valves, these pressure seal valves offer superior sealing reliability at the bonnet joint, resulting in a more compact, rigid design that reduces maintenance costs in high-temperature, high-pressure environments.

The two medium flow openings are positioned in the same direction, forming a 180° angle. The seat and disc sealing surfaces are overlayed with iron-base alloys, Co-base alloys, or carbide alloys, ensuring long-lasting performance. For larger-sized valves, a main and vice disc design is employed, with medium flowing from the top disc to the bottom disc. This design significantly reduces operational torque and enhances seat tightness, ensuring more reliable sealing performance.

Technical Specifications

» Nominal Diameter: NPS 2–24 Inch (DN50–DN600)

» Design Pressure: Class 600–2500 LB (PN10–PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, A351 CF8, CF8M, CF3, CF3M, A352 LCB

» End Connection: RF, RTJ, BW

» Design and Manufacture: ANSI B16.34, BS 1873

» Face to Face (End to End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Butt Welded End: ANSI B16.25

» Test and Inspection: API 598

» Temperature Range: -29°C to 595°C

» Medium: Water, Gas, Oil, and other Fluids

» Key Components:

A. Backup Ring: Absorbs internal pressure-induced thrust

B. Thrust Ring: Protects the soft metallic gasket from deformation

C. Gasket: Unique angular design for superior sealing

Product Features

» Short stroke for quick open/close.

» For large size and high pressure: relief cone = internal bypass.

» Disc sealing: flat sealing or throttle cone = regulating disc.

» Body seat: threaded or welded.

» Full Stellite overlay seat sealing surface.

» Easy to manufacture and maintain.

» Back seat sealing structure.

» Flexible, woven graphite packing.

» Reduce port.