ASTM A216 WCB Lift Plug Valve, API 6D, API 599, 8 IN, CL400

Key Specifications / Features

Detail Information

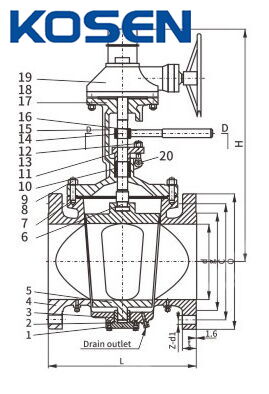

Product Name: Metal Seated Lifting Plug Valve

Design Standard: API 6D, API 599

Body Material: ASTM A216 WCB

Size: 8 Inch, DN200

Pressure: Class 400 LB, PN64

End Connection: RF Flanged

Operation: Gearbox

Lifting plug valves are designed for efficient operation in systems requiring precise flow control. When the valve is open, the handwheel is first turned to lift the plug, separating it from the sealing surface. Then, the handle is turned 90 degrees to align the plug channel with the valve body channel, completing the opening process. To close the valve, the handle is turned 90 degrees to make the plug channel perpendicular to the valve body channel, followed by turning the handwheel to lower the plug and seal the valve.

The lifting plug valve is an ideal choice for applications in the petroleum, chemical, pharmaceutical, fertilizer, and power industries. With our dedicated workshops and advanced mold casting capabilities, we are committed to meeting your plug valve needs with high-quality, reliable solutions.

Technical Specification

» Structure: Lifting Plug Valve

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: Class 150-1500 LB, PN20-PN250

» Material: Carbon Steel, Stainless Steel, Aluminum Bronze, Duplex Steel, etc.

» Design Standard: API 6D, API 599

» Face to Face: ASME B16.10

» Connection End: RF, RTJ, Butt Welding

» Test Standard: API 598, ISO 5208

» Design Temperature: -29°C to +425°C

» Applicable Medium: Water, Steam, Oil, Gas, etc.

» Operation: Lever, Gearbox, Electric, Pneumatic, Hydraulic

Working Principle

The lifting plug valve primarily consists of a valve body, valve stem, valve cover, fixing device, positioning device, sealing device, blowing pipe, lifting screw sleeve, rotating handle, and other components. To operate, rotate the lifting screw sleeve clockwise to release the valve stem. Next, turn the upper rotating handle to rotate the valve stem and position it accordingly. Once the valve is in place, rotate the lifting screw sleeve counterclockwise to lock the valve stem, completing the valve's opening or closing operation. This mechanism ensures precise control and secure sealing during operation.