ASTM A182 F316L Floating Ball Valve, API 6D, 1-1/2 IN, CL150

Key Specifications / Features

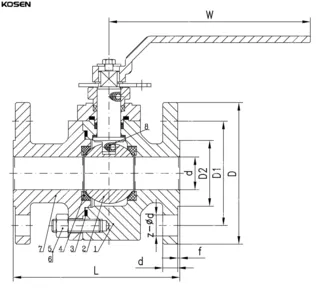

The ASTM A182 F316L Floating Ball Valve Plant produces high-quality ball valves with forged stainless steel bodies, ensuring durability and corrosion resistance. These valves feature a two-piece body design and comply with API 6D standards. Available in 1-1/2 inch (DN40) size, they are rated for Class 150 LB and PN20 pressure classes. The valves are lever-operated and come with raised face (RF) ends, making them suitable for reliable flow control in various industrial applications.

Detail Information

Product Name: Forged Floating Ball Valve, 2 Piece

Design Standard: API 6D

Body Material: ASTM A182 F316L

Size: 1-1/2 Inch, DN40

Pressure: Class 150 LB, PN20

End Connection: RF

Operation: Lever

Forged Floating Ball Valves feature a design where the ball is supported by two PTFE seats—one upstream and one downstream. The upstream pressure pushes the ball against the downstream seat, ensuring a tight shut-off for effective fluid control.

All Cast Floating Ball Valves are manufactured with high-quality castings and comply with fire-safe design certifications, including BS 6755, API 607, and API 6FA. They meet all applicable ASME standards, ensuring reliability and performance.

Our Floating Ball Valves are available in three configurations: One-Piece Uni-body, Two-Piece Split Body, Three-Piece Bolted Body

These valves are designed and manufactured according to the latest international standards, such as API 6D, ASME B16.34, and BS 5351 or their equivalents. Standard features include fire-safe design, anti-static protection, and blow-out prevention, ensuring durability and safety in demanding applications.

Technical Specifications

» Size Range: NPS 1/2-10 Inch (DN15-DN250)

» Design Pressure: Class 150-1500 LB (PN10-PN250)

» Materials: Forged Carbon Steel, Stainless Steel, Duplex Steel, or other special materials (ASTM A105N, A350 LF2, A182 F11, F22, F304, F304L, F316, F316L)

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other special materials

» Seat Materials: Nylon, RPTFE, PEEK

» End Connections: RF and RTJ flange, welded

» Operation: Handle, worm gear, electric, pneumatic

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face-to-Face (End-to-End): ASME B16.10

» Flanged Connection: ASME B16.5

» Test and Inspection: API 598, API 6D

» Butt Welded End: ASME B16.25

» Fire Safety: API 607, API 6A

» Temperature Range: -46°C to 120°C

Product Features

» Low Operating Torque

» Emergency Sealing Device

» Fireproof Structure Design

» Anti-static Structure

» Reliable Seat Sealing Structure

» Automatic Pressure Relief Towards Upstream

» Blow-out Proof Stem

» Corrosion and Sulfide Stress Resistance

» Optional Locking Device or Stem Extension

» Optional Direct Mounting to ISO 5211

» Full Port or Reduced Bore