ASTM A182 F316 Globe Valves, API 602, 2 IN, 1500 LB, PSB, BW

Key Specifications / Features

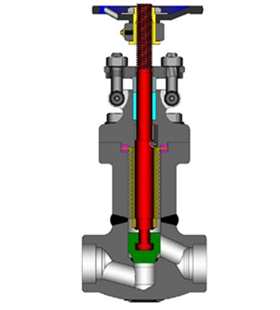

The ASTM A182 F316 Globe Valves are designed for high-performance applications. These valves feature a forged stainless steel body made from ASTM A182 F316 material, ensuring excellent corrosion resistance and durability. The valves comply with API 602 standards, guaranteeing reliability and safety. With a 2-inch (DN50) size and a pressure rating of 1500 LB (PN250), they are suitable for high-pressure systems requiring precise flow control. The pressure seal bonnet design enhances the valve's ability to maintain a tight seal under high pressure. The butt weld ends provide secure and stable connections.

Detail Information

Product Name: ASTM A182 F316 Globe Valve, Pressure Seal Bonnet

Design Standard: API 602

Body Material: ASTM A182 F316

Size: 2 Inch, DN50

Pressure: Class 1500 LB, PN250

End Connection: BW

Operation: Manual

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Pressure Seal Globe Valves are meticulously designed and manufactured in strict compliance with international standards such as API 602, ASME B16.34, DIN 3202, or their equivalents. These valves feature a compact yet extremely robust design, making them ideal for high-pressure and high-temperature applications. The optional solid CoCr alloy wedge ensures low friction and extended service life. The packing rings are precompressed to 4000 psi, providing a highly reliable seal.

For welded bonnet valves, the bonnet is threaded in and torqued to a specific engineered torque value. The body-bonnet joint is then strength-welded, offering dual protection against leakage through the body, bonnet threads, and strength-weld. The fully guided wedge reduces wear on seating surfaces, enhancing durability and performance.

Optional designs are available with features such as double packing, leak-off connections, live-loading, and a packing blowout mechanism for easy removal of old packing. These features further enhance the reliability and ease of maintenance of our Pressure Seal Globe Valves.

Technical Specification

» Size Range: 1/2-2 Inch (Forged Items)

» Temperature Range: -29°C to 595°C

» Design Pressure: Class 900-2500 LB (PN160-PN420)

» Materials: Forged Carbon Steel, Forged Alloy Steel, Forged Stainless Steel, Forged Duplex & Super Duplex Steel

» Trim Materials: 13%Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, and other special alloys

» Ends Connections: SW (Socket Weld), BW (Butt Weld), RTJ Flange

» Design & Manufacture Standards: ASME B16.34, API 602

» Face-to-Face (End-to-End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Test & Inspection: API 598, API 6D

» Butt Weld End: ANSI B16.5

» Socket-Weld Ends: ASME B16.11

Product Features

» Corrosion Resistance: The forged steel materials, after fine processing, exhibit excellent corrosion resistance. This makes the valves suitable for a variety of corrosive media and significantly extends their service life.

» Compact Design: Forged steel globe valves are designed to be more compact, with a smaller volume and reduced space occupation. This design makes them easy to install and use, particularly in working conditions where space is limited.