ASTM A105N Fixed Ball Valve, API 6D, 20 Inch, CL150, 3PC, RF

Key Specifications / Features

The ASTM A105N Fixed Ball Valve Manufacturer specializes in producing high-quality 3-piece trunnion-mounted ball valves that adhere to API 6D standards. These valves are crafted from forged carbon steel, ensuring exceptional strength and durability. With a 20-inch (DN500) diameter and rated for Class 150 LB (PN20) pressure, these valves are designed for demanding industrial applications. The RF flanged ends provide secure and reliable connections.

Detail Information

Product Name: ASTM A105N Fixed Ball Valve, 3PC

Type: Trunnion Mounted Ball Valve

Design Standard: API 6D

Body Material: ASTM A105N, Carbon Steel

Size: 20 Inch, DN500

Pressure: Class 150 LB, PN20

End Connection: RF Flanged

Operation: Gearbox

Medium: Water, Oil, Gas, etc

Temperature Range: -46°C to 120°C

Trunnion Mounted Ball Valves offer easy and smooth operation under high line pressure, thanks to carefully aligned bearings that ensure low-torque operation. The ball is securely fixed yet free to turn, providing precise flow control. Manufactured from high-quality castings, these valves are certified for fire-safe design according to BS 6755, API 607, and API 6FA, and meet all applicable ASME standards. Available in Two Piece Split Body and Three Piece Bolted Body configurations, they are designed and manufactured to the latest international standards, including API 6D, ASME B16.34, and BS 5351. Standard features include fire-safe, anti-static, and stem blow-out proof capabilities, making them ideal for a wide range of industrial applications.

Technical Specification

» Size Range: NPS 2-48 Inch (DN50-DN1200)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Body Materials: Cast Carbon Steel, Stainless Steel, Duplex, and Special Alloys

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other options

» Seat Materials: RPTFE, DEVLON, PEEK

» End Connections: Flanged RF/RTJ, Butt Welded

» Operation Types: Handle, Worm Gear, Electric, Pneumatic

» Design & Manufacturing Standards: API 6D, BS 5351, ASME B16.34

» Face-to-Face Dimensions: ASME B16.10

» Flanged Connections: ASME B16.5, ASME B16.47

» Welded Ends: ASME B16.25

» Testing & Inspection: API 598, API 6D

» Fire Safety Compliance: API 607, API 6FA

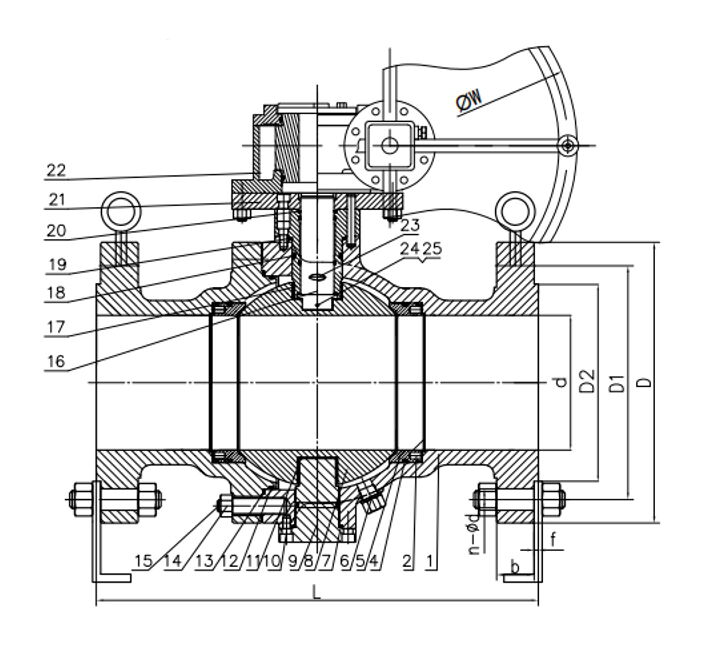

Structural Diagram

Product Features

» Double Block And Bleed(DBB)

» Low Operating Torque

» Emergency Sealing Device

» Fireproof Structure Design

» Anti-static Structure

» Reliable seat sealing structure

» Single Sealing (automatic Pressure Relief In Middle Cavity Of Valve)

» Double Sealing (double Piston)

» Safety Relief Device

» Special Structure Of Automatic Pressure Relief Towards Upper Stream

» Blow-out Proof Stem

» Corrosion Resistance And Sulfide Stress Resistance

» Optional Locking Device or Stem Extension

» Optional Direct Mounting to ISO 5211

» Full Port or Reduce Bore