3-piece Fixed Ball Valve, API 6D, ASTM A105N, 16 Inch, CL600

Key Specifications / Features

The 3-piece Fixed Ball Valve Factory specializes in producing high-quality Trunnion Mounted Ball Valves that adhere to API 6D standards. These valves are crafted from forged carbon steel, specifically ASTM A105N, ensuring exceptional strength and durability. With a 16-inch (DN400) diameter and rated for Class 600 LB and PN100 pressure classes, these valves are designed for demanding industrial applications. The RF (Raised Face) flanged ends provide secure and reliable connections.

Detail Information

Product Name: 3-piece Forged Steel Fixed Ball Valve

Type: Trunnion Mounted Ball Valve

Design Standard: API 6D

Body Material: ASTM A105N

Size: 16 Inch, DN400

Pressure: Class 600 LB, PN100

End Connection: RF Flanged

Operation: Gear Box

Medium: Water, Oil, Gas, etc

Temperature Range: -46°C to 120°C

Trunnion Mounted Ball Valves are engineered for smooth, low-torque operation even under high line pressure, thanks to precision-aligned bearings and a robust trunnion-supported design. Unlike floating ball valves, the ball remains fixed but rotates freely, ensuring reliable performance with reduced wear and superior sealing.

All cast trunnion ball valves are fire-safe certified to BS 6755, API 607, and API 6FA standards, and comply with the latest ASME, API 6D, and BS 5351 specifications. These valves are available in both two-piece split body and three-piece bolted body constructions, offering flexibility for a wide range of industrial applications. Standard features include: Fire-safe construction, Anti-static design, Blowout-proof stem

Technical Specifications

» Size Range: NPS 2-48 Inch (DN50-DN1200)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Temperature Range: -46°C to 120°C

» Body Materials: Cast Carbon Steel, Stainless Steel, Duplex Stainless Steel, Other specialty alloys

» Trim Materials:13%Cr, SS 304 / SS 304L, SS 316 / SS 316L, Custom materials available

» Seat Materials: RPTFE, DEVLON, PEEK

» End Connections: Flanged RF, RTJ, Butt Welded (ASME B16.25)

» Operation Options: Manual handle, Worm gear, Electric actuator, Pneumatic actuator

» Design & Manufacture Standards: API 6D, BS 5351, ASME B16.34

» Face-to-Face Dimensions: ASME B16.10

» Flange Standards: ASME B16.5, ASME B16.47

» Testing & Inspection: API 598, API 6D

» Fire Safety Compliance: API 607, API 6FA

Key Features

» Trunnion-mounted ball offers stable, low-torque operation under high pressure

» Fire-safe and anti-static construction for enhanced safety in critical environments

» Blowout-proof stem enhances operational reliability and safety

» Wide range of materials and sizes available for customized solutions

» Multiple operation modes (manual, electric, pneumatic) for flexible control

» Precision-machined components ensure excellent sealing performance and longevity

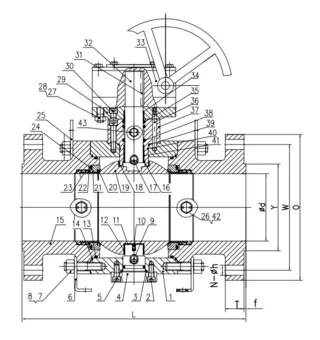

Structural Diagram

Product Features

» Double Block And Bleed(DBB)

» Low Operating Torque

» Emergency Sealing Device

» Fireproof Structure Design

» Anti-static Structure

» Reliable seat sealing structure

» Single Sealing (Automatic Pressure Relief in Middle Cavity of Valve)

» Double Sealing (Double Piston)

» Safety Relief Device

» Special Structure of Automatic Pressure Relief Towards Upper Stream

» Blow-out Proof Stem

» Corrosion Resistance and Sulfide Stress Resistance

» Optional Locking Device or Stem Extension

» Optional Direct Mounting to ISO 5211

» Full Port or Reduce Bore

Send your message to this supplier

FAQs

Yes, 3.2 certificates are available at an additional cost. We work with reputable third-party inspection agencies (TPI) such as BV, TUV, SGS, or LR, who will inspect the valves and issue signed certificates provided with the shipment.

-320x320.webp)