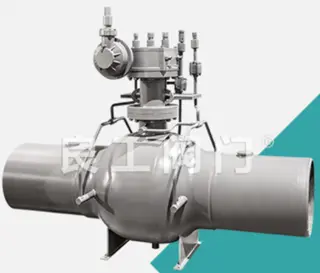

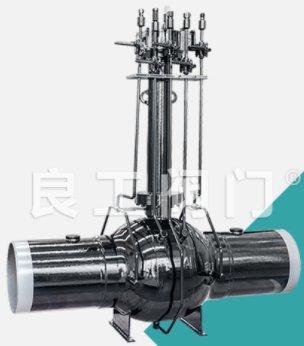

ASTM A105 Ball Valve, API 6D, DN1000, PN25, BW, Fully Welded

Key Specifications / Features

Detail Information

Product Name: ASTM A105 Fully Welded Ball Valve

Design Standard: API 6D

Body Material: ASTM A105

Size: DN1000, 40 Inch

Pressure: PN25, Class 300 LB

End Connection: BW

Operation: Gear Box

Fully Welded Ball Valves, also known as Welded Body Ball Valves, are designed for use as stop/shutoff valves in various industries, including water and gas supply systems, heat power engineering, housing, communal services, and process lines at chemical, oil-refining, and pulp-and-paper production facilities. The valve body is fully welded for enhanced durability and strength.

The materials used in manufacturing are rigorously tested for quality, including ultrasonic examination of the forging materials and liquid penetration testing of the welding slope on the connection face. A corrosion allowance is incorporated into the body wall thickness to ensure longevity.

Key components such as the carbon steel stem, fixed shaft, ball, seat, and seat ring undergo chemical nickel plating (per ASTM B733 and B656 standards) for added corrosion resistance. Optional materials with superior corrosion resistance are available, and the valve materials can be selected in accordance with NACE MR 0175/ISO 15156 or NACE MR 0103 for use in sulfurizing environments. Strict quality control measures ensure that the valves meet all applicable standards and perform optimally in demanding service conditions.

Technical Specifications

» Size Range: NPS 1/2-48 Inch (DN15-DN1200)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: Forged Carbon Steel, Forged Stainless Steel

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other special materials

» Seat Materials: RPTFE, DEVLON, PEEK

» Ends Connections: Flanged RF, RTJ, Welded

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face to Face (End to End): ASME B16.10

» Flanged Connection: ASME B16.5, ASME B16.47

» Test and Inspection: API 598, API 6D

» Butt Welded End: ASME B16.25

» Fire Safety: API 607, API 6A

» Temperature Range: -46°C to 120°C

» Medium: Water, Gas, Oil, etc.

Product Features

» Fully Welded Body: Eliminates body joint leaks.

» Body Configurations: Three-piece or two-piece options.

» Sealing Options: Metal-to-metal or soft sealing.

» Bore Options: Full bore or reduced bore.

» End Connections: Flange or welding ends.

» Double Block and Bleed: Ensures effective sealing and pressure control.

» Locking Device: Adds security.

» Piston Effects: Single or double piston effects.

» Automatic Pressure Relief: Relieves body pressure safely.

» Emergency Sealant Injection: Quick sealing in emergencies.

» Fire Safe & Anti-static: Meets fire safety standards.

» Anti-Blowout Stem: Prevents stem displacement.

» Body Vent Device: Releases built-up pressure.

» Underground Use: Suitable for underground environments.

» Extended Options: Optional bonnet and stem extensions.

» Environmentally Safe: No body joint leaks.

» Forged Steel Body: Uniform structure and toughness.